CVC means the chief value of cotton. Here CVC fabric dyeing process means the dyeing process of the fabric in which the cotton portion is higher than the polyester. So that the fabric has two types of fabric. One is cotton and the other is polyester. Here need dyeing two parts. The two-part of the fabric needs two types of dyestuff.

Cotton Part= Need Reactive dyestuff

Polyester Part= Need Disparse dyestuff

Now the question is which part will dye first in the CVC fabric?

From my experience, I can say that it’s better to dye the polyester part first. Because the polyester part needs 130⁰C to 135⁰C Cotton part needs 60⁰C to 80⁰C.

Cotton part:

Need Temperature: 60 ⁰C to 80 ⁰C

Polyester Part:

Need temperature: 130⁰C to 135⁰C

Because the polyester part needs 130⁰C to 135⁰C Cotton part needs 60⁰C to 80 ⁰C normally. So that if I dye the cotton first then the cotton can be faded during 130 ⁰C polyester dyeing.

One more thing, the polyester part dye needs reduction cleaning which will remove the reactive dyestuff.

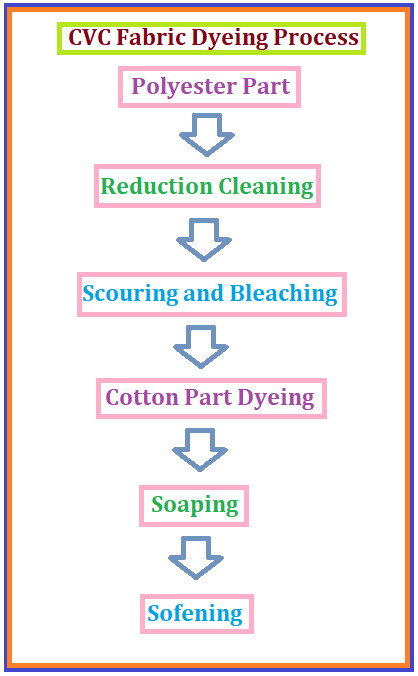

CVC Fabric Dyeing Process flow chat

Load fabric

⇩

Polyester Part dyeing

⇩

Reduction Cleaning

⇩

Scouring & Bleaching

⇩

Enzyme

⇩

Cotton Part Dyeing

⇩

Souping

⇩

Softening

⇩

Unload

Details CVC Fabric Dyeing Process step by step

Both the cotton and polyester part fabric dyeing process is stated below step by step. All the color dyeing processes are different from each other. One special color dyeing process is given below. This given process will be better for royal/turquoise-type colors. Let’s start…

Load the fabric

⇩

POLYESTER PART START

⇩

Oxalic acid+Detergent Inject = To remove impurities and neutralization

⇩

Run time 10min

⇩

Drain and wash for 5min

⇩

Acetic acid inject= For Control PH: 4.2 to 4.5

⇩

Rice the temperature at 80⁰C

⇩

Disperse dye stuff dossing 30min = For polyester part dying

⇩

Rise the temperature80 ⁰C to 95⁰C Grade 1⁰C = Grade for better penetration

⇩

Then rise temperature 95 ⁰C to 135 ⁰C Grade: 0.5 ⁰C

⇩

Run for 45min

⇩

Cooling at 135 ⁰C to 95 ⁰C grade: 1 ⁰C

⇩

Then 95 ⁰C to 79 ⁰C directly.

⇩

Check the sample = To achieve the required shade

⇩

If the shade ok then drain the dye bath

⇩

Normal hot at 80 ⁰C

⇩

Run for 10min

⇩

Wash for 10min

⇩

Caustic soda dossing 8min at temperature 50 ⁰C

⇩

Run for 5min

⇩

Rise the temperature to 80 ⁰C

⇩

Inject hydrose = For removing the loose disperse dyes

⇩

Rise the temperature to 90 ⁰C

⇩

Run for 10min

⇩

Cooling at 80 ⁰C and drain

⇩

Normal not at 90 ⁰C for 10min

⇩

Wash for 10min and drain

⇩

COTTON PART START

⇩

Detergent+Anticreasing agent+Oil remover+Peroxide stabilizer inject

⇩

Caustic soda dossing 10min

⇩

Run time 5min

⇩

Rise temperature at 70 ⁰C

⇩

Inject the Hydrogen peroxide

⇩

Rise the temperature to 100 ⁰C

⇩

Run time 60min

⇩

Cooling at 78 ⁰C

⇩

Shade check = Check the whiteness and absorbency

⇩

If ok drain

⇩

Normal hot at 80 ⁰C

⇩

Run time 10 min

⇩

Inject Acetic acid = For neutralization of Caustic

⇩

Run time 5min

⇩

Drain and wash for 5min

⇩

Peroxide killer Inject run for 5min

⇩

Drain and wash 10min

⇩

Rise temperature 55 ⁰C

⇩

Inject acetic acid = to control ph 4.5 for enzyme

⇩

Inject enzyme

⇩

Run time 60min

⇩

Shade check = For check hairiness of the fabric

⇩

If ok then drain

⇩

Wash for 10min

⇩

Leveling pH check= PH 5.5 – 6;

⇩

Levelling Dosing 600c 5 minute

⇩

Runtime 10 minute

⇩

Temperature 800c

⇩

Color Dosing 25 minute

⇩

Runtime 10 minute

⇩

1st Salt dosing 10 minutes (10%)

⇩

Runtime 5 minute

⇩

2nd Salt dosing 10 minutes (20%)

⇩

Runtime 5 minute

⇩

3rd Salt dosing 10 minutes (70%)

⇩

Runtime 10 minute

⇩

Temperature 900 C = For better dye migration

⇩

Runtime 20 minute

⇩

Colling 600 C

⇩

Salt Sample Check and Fabric Quality check = The evenness of dyes

⇩

If ok then

⇩

1st Soda dosing 20 minutes (10%)

⇩

Runtime 10 minute

⇩

2nd Soda dosing 20 minutes (20%)

⇩

Runtime 10 minute

⇩

3rd Soda dosing 25 minutes (70%)

⇩

Runtime 20 minute

⇩

Sample Check

⇩

If ok then drain or if not ok then run for more 10min and check again

⇩

If ok then drain (Rinse drain is better)

⇩

Normal, not 80 0c run 10min

⇩

Wash until clear the loose dyes (Not more than 20min)

⇩

Inject soaping agent

⇩

Rise 90 0c and run 10min

⇩

Check shade if the ok drain

⇩

Wash clear

⇩

Fixing agent dos 5min

⇩

Runtime 10min

⇩

Wash clear

⇩

Softener dossing 7min

⇩

Check softness if ok

⇩

Unload and deliver to finishing

Which fabric is better in a dyeing process Cotton or Polyester?

Fabrics like cotton and polyester are often used for dying, and the choice depends on a number of things. Cotton is a natural fibre that absorbs a lot of water and takes dyes very well. It is perfect for making colors that stay bright and rich for a long time. Cotton is also more environmentally friendly as it is biodegradable and renewable.

On the other hand, polyester is a synthetic fibre that doesn’t fade, shrink, or wrinkle. Polyester fabrics tend to keep their colors well and last a long time, so they are good for long-term use. But polyester is less absorbent than cotton, which can make colors look duller and make it harder to breathe.

Conclusion:

CVC Fabric Dyeing Process is two different processes in one combination. This is so lengthy process. It can be short according to the behavior of dyes and chemicals. I think it is the details process. I think it will clear all the questions in your mind.

Research Link

You may read some other articles

- Which Dyeing Process Produces The Most Colorfast Fabric?

- Tried and Tested Standard Operating Procedures (SOP) For the Dyeing Process

FOR MORE INFO VISIT KNIT DYEING DETAILS

[…] CVC Fabric Dyeing Process|Step By Step Details […]

[…] CVC Fabric Dyeing Process|Step By Step Details […]