Cotton Linen Blend Fabric is a popular choice for many textile products due to its unique combination of properties. This fabric combines the strength and durability of cotton with the softness and breathability of linen. It is commonly used in clothing, home textiles, and upholstery due to its versatile nature.

We will explore the basics of Cotton Linen Blend Fabric, including its composition, properties, and various applications. We will also dive into the knitting, dyeing, and finishing development of this fabric, providing you with a comprehensive guide on everything you need to know about Cotton Linen Blend Fabric. Whether you’re a textile enthusiast or a professional in the industry, this guide will help you gain a better understanding of Cotton Linen Blend Fabric and its uses.

What is Linen Fabric?

Linen fabric is a semi-transparent fabric made from the thread of the flax plant. It has a cool, formal feel when compared to other fabrics. Linen is a natural fabric made of fibers that comes from the flax plant. It is easy to care for, it drapes well, and it has a soft hand. It does not fray easily and is often used for sheets that are considered more eco-friendly than silk or cotton. Linen fabric can dye at home as well as in the textile industry. But for the home, it needs some special dyes.

What is Cotton Linen Blend Fabric?

Cotton linen blend fabric is a fabric made up of cotton and linen. The cotton-linen fabric is an eco-friendly option for textile production due to the natural fibers it contains. It is also odorless, holds up well against wrinkles, has antimicrobial properties, and provides natural UV protection.

Cotton linen blends are typically used in summer clothes because they are cool to the touch and breathable. Cotton-linen blend fabric is a combination of cotton fibers and linen fibers. Cotton-linen blends are often used in apparel because the natural absorbency of the linen fibers helps to wick moisture away from the skin. This also makes it attractive for those seeking to avoid the buildup of bacteria.

Is Cotton Linen Fabric Good?

Cotton linen fabric is a good option for those who are looking to create drapes, curtains, or other home decor items. This type of fabric has the drape and softness of cotton but also the durability of linen. For this reason, it is a great choice for those who want to make their own curtains or take advantage of what they have at home to work on projects without having to purchase new materials.

Cotton linen fabric is a great fabric for those who do not want to use polyester and wool fabrics. It is made from cotton and linen, which is an eco-friendly material that can be hand-washed or machine-washed. This fabric is comfortable and it does not hold onto odors as much as most other fabrics. Cotton linens are a great option for those looking for eco-friendly, comfortable, easy-to-wash materials.

Knitting, Dyeing, and Finishing Development of Cotton Linen Blend Fabric

Cotton linen blend fabric is a special fabric all over the world. Now I show here the complete knitting, dyeing, and finishing development of an 80% Cotton 20% linen fabric.

I will show the target fabric which I got after the experiment.

Target Parameter of the fabric:

Fabric Type: Cotton linen single jersey.

Composition: 85% Organic cotton + 15% Linen

Color Name: Rose 172330 tex

Fabric Diameter: 150 cm open.

Fabric GSM: 150.

Knitting of CVC 80%+20% Cotton linen blend fabric:

The imported Yarn parameter:

| Yarn count and Type | 28/1 (85% Organic Cotton+15% linen) |

| Yarn composition | 85% Organic Cotton+15% linen |

| Yarn lot | According to supplier |

| Yarn Brand | Not shareable |

Knitting Parameter of CVC 80%+20% Cotton linen blend fabric

| Machine Dia and Gauge | 34*20 |

| Total needle | 2100 |

| Stitch length | 28.0 |

| Machine No | Na |

| Machine Brand | Unitex |

| Machine RPM | 16 |

| Grey Width | 210 cm open |

| Grey GSM | 125 |

| Gray Wash | |

| Gray Wash GSM |

Dyeing of CVC 80%+20% Cotton linen blend fabric:

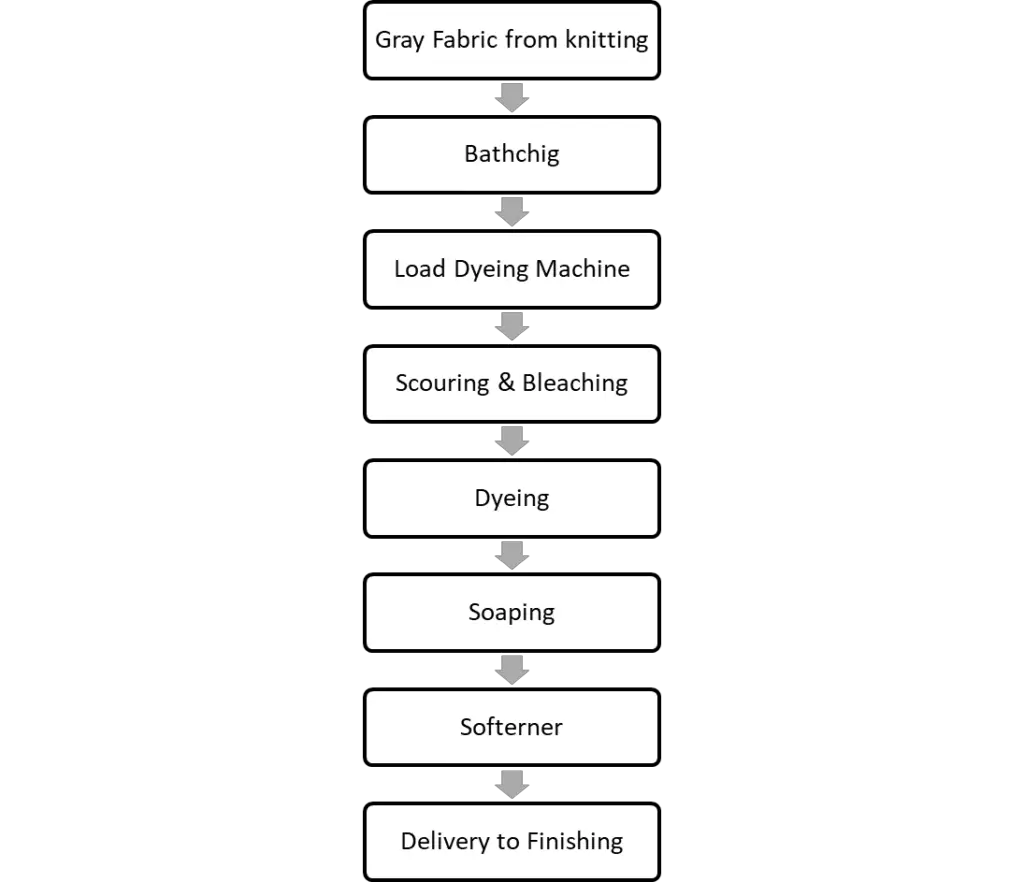

Here will discuss the dyeing flow chart, dyeing process, dyeing recipe, and Dyeing sequence image

Dyeing flow chart of CVC 80%+20% Cotton linen blend fabric :

Description of the flow chart:

Collect from knitting gray store

⇩

Batching

⇩

Provide a batch bard which contains all the related information

⇩

Load the fabric according to batch card

⇩

Scouring and Bleaching

⇩

Dyeing

⇩

Soaping

⇩

Softening

⇩

Delivery to finishing

Dyeing Process of CVC 80%+20% Cotton linen blend fabric:

Load the fabric

⇩

Anticreae+Detergent Inject = To remove impurities

⇩

Wash and Drain

⇩

Detergent+Anticreasing agent+Oil remover+Peroxide stabilizer inject

⇩

soda dossing 10min

⇩

Run time 5min

⇩

Rise temperature at 70 ⁰C

⇩

Inject the Hydrogen peroxide

⇩

Rise the temperature to 98 ⁰C

⇩

Run time 60min

⇩

Cooling at 78 ⁰C

⇩

Shade check = Check the whiteness and absorbency

⇩

If ok drain

⇩

Normal hot at 80 ⁰C

⇩

Run time 10 min

⇩

Inject Acetic acid = For neutralization of Soda

⇩

Run time 5min

⇩

Drain and wash for 5min

⇩

Peroxide killer Inject run for 5min

⇩

Drain and wash 10min

⇩

No Enzyme = Linen will damage if it done

⇩

Leveling pH check= PH 5.5 – 6;

⇩

Levelling Dosing 600c 5 minute

⇩

Runtime 10 minute

⇩

Color Dosing 25 minute

⇩

Runtime 10 minute

⇩

Salt dosing 10 minutes

⇩

Runtime 10 minute

⇩

Salt Sample Check and Fabric Quality check = The evenness of dyes

⇩

If ok then

⇩

1st Soda dosing 20 minutes (10%)

⇩

Runtime 10 minute

⇩

2nd Soda dosing 20 minutes (80%)

⇩

Run time 15min

⇩

Sample Check

⇩

Shade ok and then drain (Rinse drain is better)

⇩

Normal, not 80 0c run 10min

⇩

Wash until clear the loose dyes (Not more than 20min)

⇩

Inject soaping agent

⇩

Rise 90 0c and run 10min

⇩

Check shade if the ok drain

⇩

Wash clear

⇩

Fixing agent dos 5min

⇩

Runtime 10min

⇩

Wash clear

⇩

Softener dossing 7min

⇩

Check softness if ok

⇩

Unload and deliver to finishing

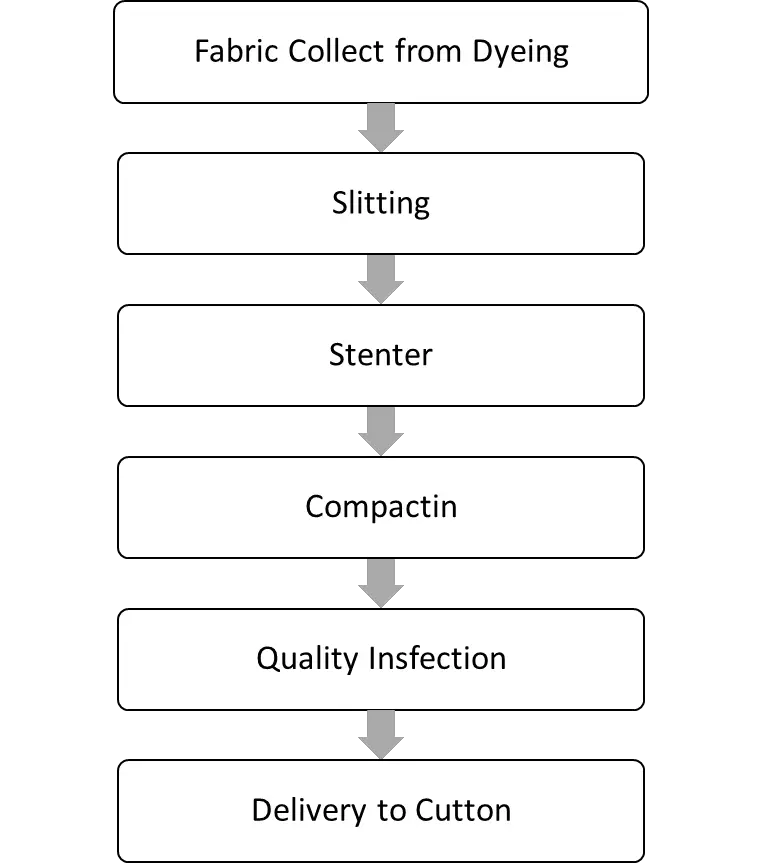

Finishing of CVC 80%+20% Cotton linen blend fabric :

Finishing flow chart:

Slitting Parameter:

| Machine Speed | 40 |

| Padder pressure | 1.5 kg |

| Over Feed | |

| Fabric In Diameter | 34 |

| Fabric Out Diameter | 160 |

Stenter/Compacting

| Stanter/Dryer | Compacting | ||

| Width set | 150 | ||

| Over Feed | 59% | Temperature | 120 |

| Temperature | 120 | Steam Pressure | 30 |

| RPM/ Speed | 21 | Width set | 150 |

| Padder Pressure | 3+2 | Over feed% | 35% |

| Vibration | RPM/Speed | 18 | |

| Softener Type | Cationic | Compaction% | |

| After Dry Width | 142 | After Width | 140 |

| After Dry GSM | 133 | After GSM | 142 |

| Palla Wash gsm | 164 |

Final width= 138 Final GSM=164

Shrinkage with tumble dry:

Length=-8%

Width=-7%

SP%=2%

Comments: We Need Palla wash to maintain the GSM 164.

Testing of the CVC 80%+20% Cotton linen blend fabric:

To check the different quality parameters fabric was given to the testing lab for physical and chemical testing which are stated below. Here I show the actual result which I got. We took preventive steps by checking the parameter.

Conclusion of Test Results:

| Sl. No | Test Name | Results (A) |

| 01 | Dimensional Stability To Washing | Pass |

| 02 | Spirality After Washing | Pass |

01. Dimensional Stability To Washing

Test Method:ISO 6330:2012

Test condition: Normal Program, Machine wash@ 30°C, Line dry, Used Domestic washing Machine Miele, 20gm Ariel reference Detergent with 2.0kg load.

| Sample (A) | After One Wash | |

| Direction | Result | Client Requirement |

| Length | +3.0% | ±5% |

| Width | -2.0% |

02. Spirality After Washing

Test Method: ISO 6330:2012

Test condition: Normal Program, Machine wash@ 30°C, Line dry, Used Domestic washing Machine Miele, 20gm Ariel reference Detergent with 2.0kg load.

| Sample (A) | Result | Client Requirement |

| Spirality | 0.0% | 2% |

Conclusion:

Cotton linen blend fabric is a popular and eco-friendly option for textile production. It combines the absorbency and natural properties of linen with the softness and durability of cotton. The process of knitting, dyeing, and finishing cotton linen blend fabric involves various quality checks to ensure the final product meets desired standards.

We’ve talked about and gone into more detail about what is cotton-linen blend fabric. It is a versatile and comfortable material that can be used for a wide range of things, from decorating your home to making summer clothes. Experiments about knitting, dying, and finishing are also shown to show how the process works.

FAQ

Is Cotton Linen Blend Stretchy Vs Pure Cotton or Pure Linen?

A cotton-linen blend tends to be less stretchy than either pure cotton or pure linen. Pure cotton can have some stretch if it has spandex or elastane in it, but pure linen has almost no stretch. Cotton linen blends tend to last longer than pure linen and feel softer than pure cotton.

Overall, a fabric’s ability to stretch depends on its blend, how it was made, and whether or not it has any stretch fibers.

Research link:

You may read some other articles

- Can You Use Fabric Paint on Linen

- Will Tie Dye Work on 60 Cotton 40 Polyester

- The Ultimate Guide to Knitting, Dyeing, and Finishing CVC 60%+40% French Terry Fabric

- 5 Best Natural Dye For Cotton: Interesting Insights On Why Natural Dyes For Cotton Is The Best?

[…] What Is Cotton Linen Blend Fabric? It’s Knitting, Dyeing,& Finishing Development […]

[…] What Is Cotton Linen Blend Fabric? It’s Knitting, Dyeing,& Finishing Development […]

[…] What Is Cotton Linen Blend Fabric? It’s Knitting, Dyeing,& Finishing Development […]