Cotton Interlock knit fabric is a cotton fabric that is knitted on the same machine as the knitwear. It has interlocking ribs, so it’s stretchier than other fabrics and can be worn by people of different sizes. The fabric is also made up of two rows of yarns which are twisted together to form alternating rib patterns. Cotton Interlock is made up of 100% cotton fibers, making it breathable and soft for the wearer.

Cotton Interlock knit fabric is an often-used fabric for everyday garments. It is also commonly used in hospital gowns, children’s clothes, and linings for jackets. The fabric is made of cotton fibers woven together to create a tight weave that does not unravel or pull apart easily. This provides durability and allows the fabric to maintain its shape after washing.

Knitting, Dyeing, and finishing development of 100% Cotton Interlock knit fabric

Cotton Interlock knit fabric is a special type of fabric in the textile industry. I am sharing my personal development of a 100% cotton interlock fabric. I am sharing the actual data which I got. This is about the development from yarn to finished fabric. Let’s start…..

I will show the target fabric which I got after the experiment.

Target Parameter of the fabric:

Fabric Type: Interlock knit fabric

Composition: 100% cotton

Color Name: Affogat

Fabric Diameter: 185 cm open.

Fabric GSM: 240.

Knitting of 100% Cotton Interlock knit fabric :

The imported Yarn parameter:

| Yarn count and Type | 34/1 Cotton |

| Yarn composition | 100% cotton |

| Yarn lot | According to supplier |

| Yarn Brand | Not shareable |

Knitting Parameter of 100% Cotton Interlock knit fabric:

| Machine Dia and Gauge | 36*24 |

| Total needle | 5428 |

| Stitch length | 28.0 |

| Machine No | Na |

| Machine Brand | Unitex |

| Machine RPM | 15 |

| Grey Width | 190 cm open |

| Grey GSM | |

| Gray Wash | |

| Gray Wash GSM |

Dyeing of Cotton Interlock knit fabric :

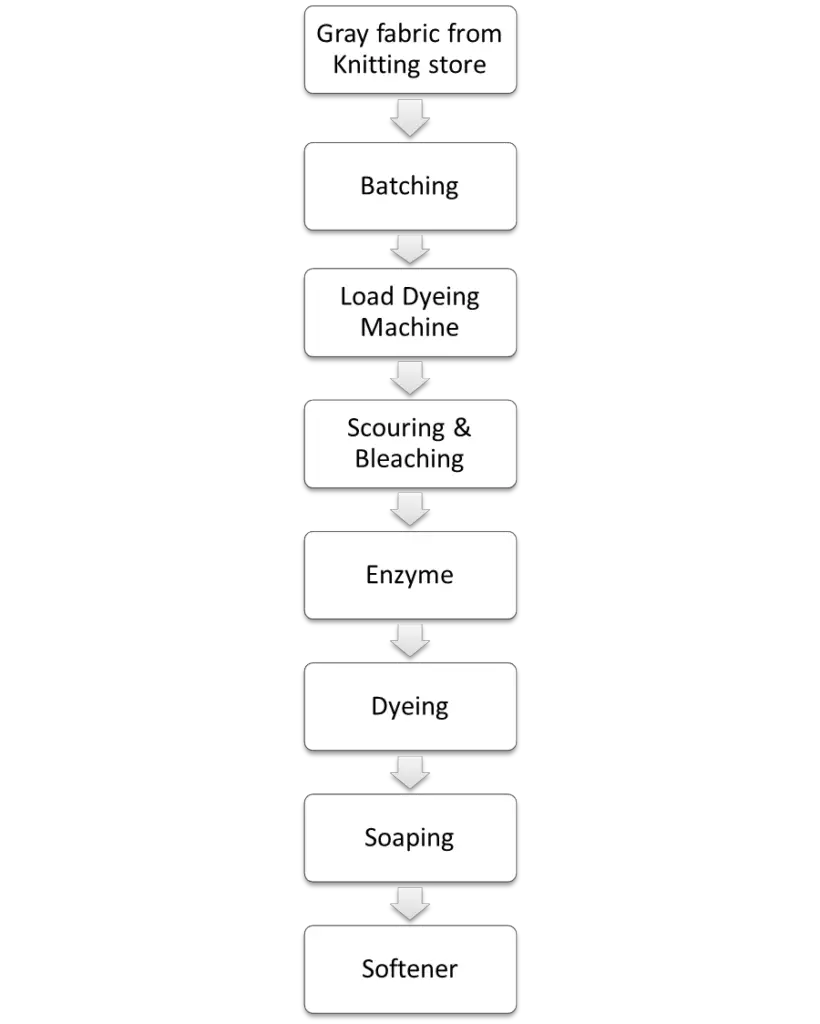

Here will discuss the dyeing flow chart, dyeing process, dyeing recipe, and dyeing sequence image

Dyeing flow chart of 100% Cotton Interlock knit fabric :

Description of the flow chart:

Collect from knitting gray store

⇩

Batching

⇩

Provide a batch bard which contains all the related information

⇩

Load the fabric according to the batch card

⇩

Scouring and Bleaching

⇩

Enzyme

⇩

Dyeing

⇩

Soaping

⇩

Softening

⇩

Delivery to finishing

Dyeing Process of a Dyeing flow chart of 100% Cotton Interlock knit fabric:

Load the fabric

⇩

Anticreae+Detergent Inject = To remove impurities

⇩

Wash and Drain

⇩

Detergent+Anticreasing agent+Oil remover+Peroxide stabilizer inject

⇩

Caustic soda dossing 10min

⇩

Run time 5min

⇩

Rise temperature at 70 ⁰C

⇩

Inject the Hydrogen peroxide

⇩

Rise the temperature to 98 ⁰C

⇩

Run time 60 min

⇩

Cooling at 78 ⁰C

⇩

Shade check = Check the whiteness and absorbency

⇩

If ok drain

⇩

Normal hot at 80 ⁰C

⇩

Run time 10 min

⇩

Inject Acetic acid = For neutralization of Soda

⇩

Run time 5min

⇩

Drain and wash for 5min

⇩

Peroxide killer Inject run for 5min

⇩

Drain and wash 10min

⇩

Rise the temperature at 55 0c

⇩

Control PH= 4.5 with acetic acid

⇩

Inject Enzyme

⇩

Run time 40min

⇩

Check sample hairiness

⇩

If ok then raise the temperature at 80 0c

⇩

Run 5min

⇩

Drain and wash the enzyme dust

⇩

Start dyeing

⇩

Leveling pH check= PH 5.5 – 6;

⇩

Levelling Dosing 600c 5 minute

⇩

Runtime 10 minute

⇩

Color Dosing 25 minute

⇩

Runtime 10 minute

⇩

Salt dosing 10 minutes

⇩

Runtime 10 minute

⇩

Salt Sample Check and Fabric Quality check = The evenness of dyes

⇩

If ok then

⇩

1st Soda dosing 20 minutes (10%)

⇩

Runtime 10 minute

⇩

2nd Soda dosing 20 minutes (80%)

⇩

Run time 15min

⇩

Sample Check

⇩

Shade ok and then drain (Rinse drain is better)

⇩

Normal, not 80 0c run 10min

⇩

Wash until clear the loose dyes are (Not more than 20min)

⇩

Inject soaping agent

⇩

Rise 90 0c and run 10min

⇩

Check shade if the ok drain

⇩

Wash clear

⇩

Fixing agent dos 5min

⇩

Runtime 10min

⇩

Wash clear

⇩

Softener dossing 7min

⇩

Check softness if ok

⇩

Unload and deliver to finishing

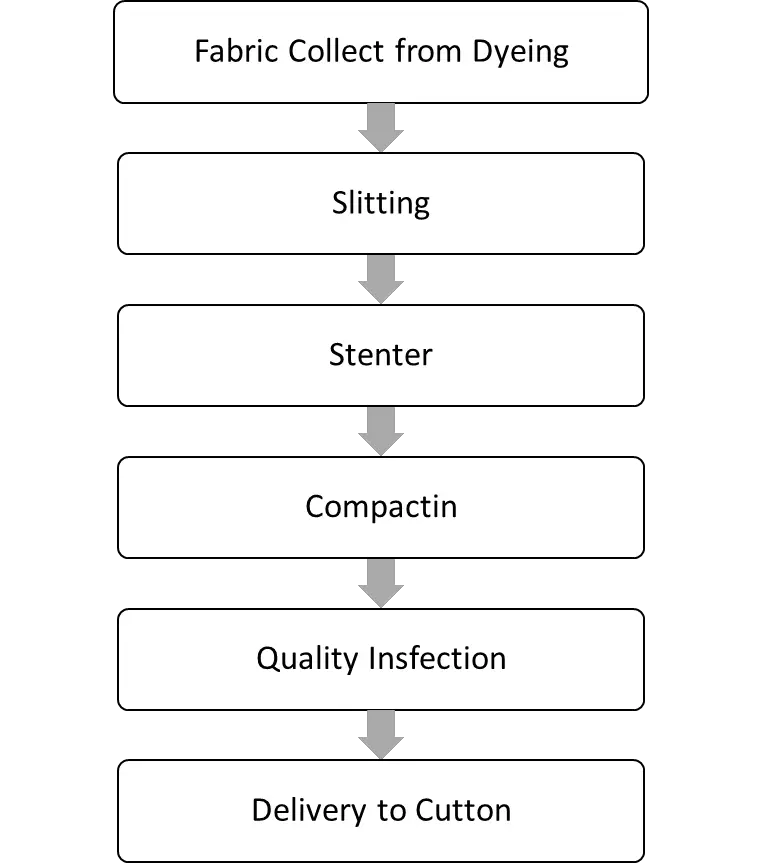

Finishing of the Dyeing flow chart of 100% Cotton Interlock knit fabric:

Finishing flow chart:

Slitting Parameter:

| Machine Speed | 40 |

| Padder pressure | 1.5 kg |

| Over Feed | |

| Fabric In Diameter | 36 |

| Fabric Out Diameter | 185 |

Stenter/Compacting

| Stanter/Dryer | Compacting | ||

| Width set | 188 | ||

| Over Feed | 59% | Temperature | 120 |

| Temperature | 130 | Steam Pressure | 30 |

| RPM/ Speed | 20 | Width set | 180 |

| Padder Pressure | 3+2 | Over feed% | 35% |

| Vibration | RPM/Speed | 12 | |

| Softener Type | Cationic | Compaction% | |

| After Dry Width | 185 | After Width | 180 |

| After Dry GSM | 182 | After GSM | 235 |

| Palla Wash gsm | 255 |

Final width= 180 Final GSM=235

Shrinkage with tumble dry:

Length=-5%

Width=-3%

SP%=2%

Shrinkage with Line dry:

Length=-2.4%

Width=-0.7%

SP%=0.0%

Comments: I think All are most same for bulk production.

Testing of 100% Cotton Interlock knit fabric

Conclusion of Test Results:

| Sl. No. | Test Name | Results (A) |

| 01 | Dimensional Change in Washing | Pass |

| 02 | Spirality After Washing | Pass |

| 03 | Color Fastness to Washing | Pass |

| 04 | Color Fastness to Rubbing | Pass |

| 05 | Color Fastness to Perspiration | Pass |

| 06 | Bursting Strength | Pass |

| 07 | Pilling Resistance | Pass |

| 08 | Mass Per Unit Area | Pass |

01. Dimensional Change in Washing

Test Method : ISO 5077+ ISO 3759+ ISO 6330: 2012

Test Condition: Normal Program, Machine Wash@40°C, Line Dry in Shade, Used domestic washing machine Wascator, 20 gram ECE Reference Detergent with 2.0kg load.

| Sample (A) | After One Wash | |

| Direction | Result | Client Requirement |

| Length | -2.4% | ±5% |

| Width | -0.7% |

Remark: (+) Means Extension And (-) Means Shrinkage

02. Spirality After Washing

Test Method: ISO 16322-3: 2005

Test Condition: Mild Program, Machine Wash@30°C, Line Dry in Shade, Used domestic washing machine Wascator, 20 gram ECE Reference Detergent with 2.0kg load.

| Sample (A) | Result | Client Requirement |

| Spirality | 0.0% | Max 4% |

03. Color Fastness To Washing

Test Method: ISO 105 CO6-A1S:2010

Test Condition: Temperature at 40 degrees, Time 30 min, Detergent 4g/l ECE With 10 Steel Balls

| Sample (A) | Result | Client Requirement |

| Color Change | 4 | 3-4 |

| Color staining | 3-4 | |

| -Acetate | 4-5 | |

| -Cotton | 4-5 | |

| -Nylon | 4-5 | |

| -Polyester | 4-5 | |

| -Acrylic | 4-5 | |

| -Wool | 4-5 |

04. Color Fastness To Rubbing

Test Method: ISO 105 X12:2016

Test Stage: As Received Stage

| Sample (A) | Result | Client Requirement |

| Dry Rub | 4-5 | 3-4 |

| Wet Rub | 4-5 | 3 |

05. Color Fastness To Perspiration

Test Method: ISO 105 E04:2013

Test Condition: Temperature at 37±2 degrees, Time 4 hours.

| Sample (A) | Result | Client Requirement | |

| Acid | Alkaline | ||

| Color Change | 4 | 4 | 4 |

| Color staining | 3-4 | ||

| -Acetate | 4-5 | 4-5 | |

| -Cotton | 4-5 | 4-5 | |

| -Nylon | 4-5 | 4-5 | |

| -Polyester | 4-5 | 4-5 | |

| -Acrylic | 4-5 | 4-5 | |

| -Wool | 4-5 | 4-5 |

06. Bursting Strength

Test Method: ISO 13938-2:2019, used 50 cm2 dia

Test Stage: As Received Stage

| Sample (A) | Result | Client Requirement |

| Average | 210.9 kPa | 125 kPa |

07. Resistance Of Pilling (ICI Box Method)

Test Method: EN ISO 12945-1:2020

| Sample (A) | Result | |||

| After 10800 Cycle | Length Direction | Width Direction | ||

| Grade | 4 | 4 | ||

| Note: Pill & Fuzzy effects are observed |

Visual Assessment

| Grade | Description |

| 5 | No Change |

| 4 | Slight Surface fuzzing and/or partially formed pills. |

| 3 | Dense surface fuzzing and/or severe pilling. Pills of varying size and density covering the whole of the specimen surface. |

| 2 | Moderate surface fuzzing and/or moderate pilling. Pills of varying size and density cover the specimen surface. |

| 1 | Dense surface fuzzing and/or severe pilling. Pills of varying size and density cover the whole of the specimen surface. |

08. Mass Per Unit Area

Test Method: EN 12127: 1998

Test Stage: As Received Stage

| Sample (A) | Result | Client Requirement |

| Average | 228.0 g/m2 | 240 g/m2(±5%) |

Conclusion:

We discuss “What Is Cotton Interlock knit fabric” and I think there is no confusion about it. I share here the complete knitting dyeing and finishing process and experiment. All of the information is a self-practical experiment.

Research link:

You may read some other articles

- The Ultimate Guide to Knitting, Dyeing, and Finishing CVC 60%+40% French Terry Fabric

- What Is Coolmax Fabric Made Of?

- 100% Cotton Fabric Knitting Dyeing Process (Reactive dye), Practical Documentation 2023

- Knitting, Dyeing, and Finishing CVC 60%+40% French Terry Fabric

[…] What Is Cotton Interlock knit fabric? It’s Knitting, Dyeing, Finishing Development. […]

[…] What Is Cotton Interlock knit fabric? It’s Knitting, Dyeing, Finishing Development. […]

[…] What Is Cotton Interlock knit fabric? It’s Knitting, Dyeing, Finishing Development. […]