Hey, our topic is “Can You Dye Polyester And Elastane Fabric?“. Yes, there is a doubt about all the learners. But the answer is yes. Normally we think that the polyester dyeing temperature is 130 degrees temperature and the lycra /elastane dyeing temperature is 102 degrees centigrade. And another important factor is elastane can damage during high temperatures. Yes, all of the information is right. Now I am discussing how it can be possible by considering all the parameters.

Polyester is a polyethylene terephthalate (PET) produced from ethylene glycol and terephthalic acid. Its dyeing is a thermodynamic process. Most using dyes is dispersed dye. These dyes interest the inner fiber during dyeing. On the other hand, elastane is a Polyurethane-Polyurea copolymer. Normally, acid dyes are used to dye this fiber.

Yes, it is indeed a difficult task in the present textile to dye polyester fabric that contains elastane. But I have done it many times. Of course, I will show my experiment on this topic. Sometimes I damaged all the elastane and in the last, I set a successful process.

Dyeing process of 95% polyester and 5% elastane fabric

In dyeing, we consider the part from gray fabric to dyed fabric. That means we collect the fabric from knitting and delivery to finishing. All the processes are discussed below with practical experience.

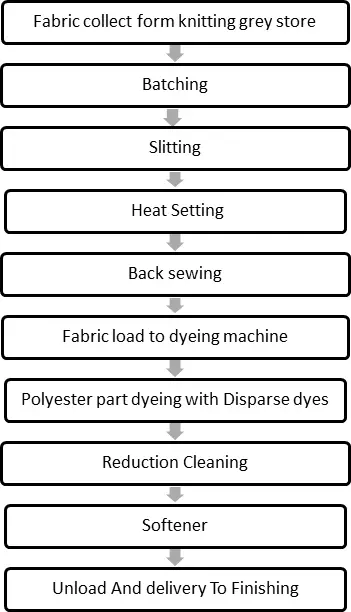

Flow chart of polyester elastane fabric dyeing process

Short description of all the processes for better understanding.

Collect fabric from the knitting gray store:

After completion, the fabric is delivered to the Grey store. The dyeing department will collect this fabric according to the order requirement and send it to a batch section of dyeing.

Batching:

After getting the grey fabric batch section will prepare the batch according to order and machine capacity of dyeing. A batch card is prepared here to store all information regarding knitting, dyeing, and finishing parameters.

Slitting:

We open the fabric with the slitting machine. After knitting fabric comes in a tube formation. But this fabric contains elastane, for this reason, it needs a heat setting. Because our fabric needs in open formation in cutting section. So that we have to open the fabric for the heat set. We can also heat set in tube format. In that case no need for slitting.

Heat setting:

Heat setting is so important factor for polyester elastane fabric. This is done to make the fabric stable. Because We know that elastane is totally unstable fiber.

Back Sewing:

Back sewing means we close the two ends of the fabric width. So that fabric is in tube format again. Because dyeing machine needs a tube format fabric for avoiding some faults like side shading, Ends shading, running shade, twisting on the nozzle, etc.

Fabric load to dyeing machine:

In this stage, we load the fabric according to the batch cards.

Dyeing:

Fabric is dyed here according to the process.

Unload and delivery to finishing:

After dying the fabric, it is delivered to the finishing.

Dyeing process steps of polyester elastane fabric:

Color Name : Black

Batch quantity : 10kg.

Dyeing Type : Disperse dying

M:L : 1: 10

Enzyme Type : No.

Cycle Time : 2.5 min.

Dyeing recipe:

Oxalic acid : 1 G/L

Anticreasing agent : 1 G/L

Polyester Levelling : 1 G/L

Dispersing agent : 1 G/L

Dyes : Recipe according to the lab.

Sodaash : 2 G/L

Hydrose : 2G/L

The dyeing process step by step is given below

Oxalic acid and increasing agent hot 80’c temperature

Run 10min

Drain and fill

Control Ph 4.5

Leveling of disperse dyeing and Antecreaseing agent injects

Run 10min

Rise temperature 80’c

Color(disperse dyes) dossing 30min

Run 10min

Rise temperature 130’c Grade 0.5

Run 45min

Cooling at 80’c Grade 0.5

Check the shade

If ok drain the dye batch

Reduction Cleaning

Dossing the soda ash lt for 10min

then rise the temperature at 80’c

rise the chemical tank temperature 80’c also

inject the hydro’s

rise the temperature to 95’c

run 15min

cooling at 80’c drain

Neutralize the fabric with acetic acid 50,c temperature

run 10min

Drain and wash clean

Polyester softener dossing 5min

Runtime 15min

Unload the Fabric and Deliver it to finishing

The complete experiment on the topic “Can You Dye Polyester And Elastane Fabric?”

1st step: The image of Grey Fabric that I collect from knitting is given below

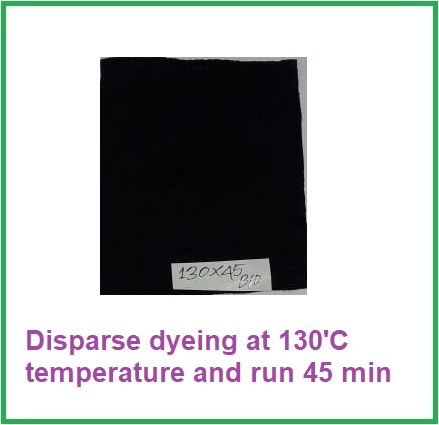

2nd step: Dying the fabric in the dyeing machine at 130’C temperature and run for 45min. The sample I got is given below

3rd step: Reduction cleaning sample which I got. An image of reduction cleaning is given below

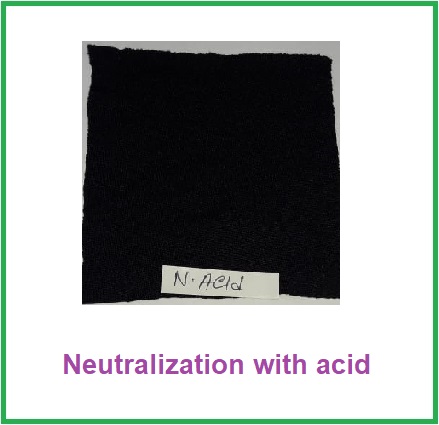

4th step: The neutralization image which I got is given below

5th and final step: The sample image after the softener is given below

Then the fabric is delivered to finishing. After controlling all the parameters we got the actual fabric. After that, we send 1 meter of fabric to the lab section for all required testing. If all test report is ok, then we delivered the fabric to cutting.

The finished polyester elastane fabric image is given below:

The finished fabric video of polyester elastane is given below:

This video can show:

- The quality of elastane is good.

- The recovery of elastane is good.

- There is no elastane out.

- Smoothness and silky touch are good.

Conclusion:

Here we discussed the topic “can-you-dye-polyester-and-elastane-fabric”. Yes, it is possible. But is good to dye separately and then knit the fabric for getting a better result. Sometimes lycra will be out when it is dyed at 130’c temperature. You must consider some points when you choose polyester elastane fabric dyeing. which are defined below:

- High-quality elastane/ lycra should have to use.

- The headset will have to do carefully.

- One shoot dye will give a better result.

- Finishing should be done with care.

- In fabric construction, lycra should not visible on the face side of the fabric. Because sometimes it creates a melange effect. Especially in cotton elastane fabric.

Research Links:

You May Also Read Some Other Related Articles:

- How To Dye Polyester Fabric At Home

- What Is Coolmax Fabric Made Of?

- Exclusive 75% Viscose Ponte Roma Fabric Collection

- Exclusive White T-Shirt by Tim McGraw: Update 2023

- 6 Best Screen Printing Ink For Dark Fabric 2023

You can find us on:

[…] Can You Dye Polyester And Elastane Fabric? A 100% Practical Experiment […]

[…] Can You Dye Polyester And Elastane Fabric? A 100% Practical Experiment […]

[…] Can You Dye Polyester And Elastane Fabric? A 100% Practical Experiment […]

[…] Can You Dye Polyester And Elastane Fabric? A 100% Practical Experiment […]