Cotton is the most popular useable fiber in the world. Here we discuss the 100% cotton fabric knitting dyeing process, dyeing process with reactive dye, finishing process, and flow chart of knitting, dyeing, and finishing process with complete practical documentation which I did recently. Dyeing cotton fabric at home is also a common practice in the present world.

Practical Documentation of a 100% Cotton Heavy Single Jersey Fabric Knitting Dyeing (color) Process:

Here I am sharing one of the knitting dyeing processes with all documents that I did at the factory level. If you use this parameter at the factory level, you will get the same result. Let’s enjoy…..

Target parameter:

| Fabric type | Heavy Single Jercy |

| Composition | 100% organic cotton |

| Color Name /Pantone | 191008tcx |

| Shade % | 0.02 |

| Repaired Diameter | 150 CM (Open) |

| Required GSM | 280 |

| Special Note | The special fabric needs special care to avoid crease marks, long marks |

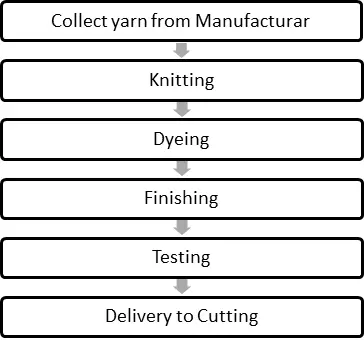

Overall 100% cotton Heavy single Jercy Fabric Knitting Dyeing and Finishing Process Flow Chart:

To get the target fabric we set a target route for the overall process which I have given below-

100% cotton fabric knitting process

The step-by-step cotton fabric knitting process is discussed here

Imported yarn parameter:

| Yarn count and Type | 24 S/2 organic cotton |

| Yarn Composition | 100% organic cotton |

| Yarn Composition | Reported company |

| Yarn Brand | Reported company |

Knitting setting Parameter:

The setting parameter of knitting to get our target fabric is below table.

| Machine Dia and Gauge | 30 & 16 |

| Total Needle | 1500 |

| Stitch length | 39 |

| Machine Brand | Jiun Long |

| Machine RPM | 17 |

The parameter after Knitting of 100% cotton heavy jercy fabric:

After completing knitting we get the fabric parameter stated below table.

| Grey fabric width | 190 cm (Open) |

| Gray GSM | 240 |

100% cotton fabric dyeing process with reactive dye:

Here we have completed knitting this heavy jersey fabric. Now we have the dye the fabric. We discussed below all the flow processes of dyeing which we did for this batch.

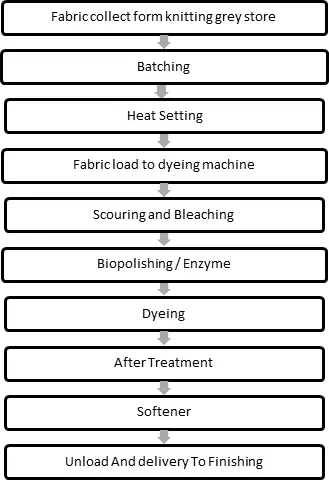

Cotton fabric dyeing process flow Chart:

Short description of cotton fabric dyeing process flow chart:

I am giving here a short description for a better understanding of all the processes.

Batching:

Knitted fabric is collected from the knitting gray store and created a batch here. Batch means the prepared fabric in dyeable format. Knitting is done roll to roll. Here fabric creates a rope according to the loading capacity of the dyeing machine. A batch card is also created for storing all the knitting and dyeing process parameters.

Heat Setting for the 100% cotton Heavy single jersey knitted fabric with a practical example:

Heat setting is the process of a starter machine to control the dimensional stability of the fabric. This process is added to control the mechanical deformation of a knitted fabric like crease marks, long marks, Fabric side twisting, etc. This process is not needed for all the fabric. It is not possible to state all the fabric types. I am giving only some of the fabric which is in my mind right now.

The heat setting is done for the fabric category which is given below table:

| Fabric Type | GSM Range |

| Elastane / lycra fabric | All gsm fabric |

| Single jersey fabric | 180 and above |

| Fleace / terry | 350 and above |

| 100% polyester fabric/ PC fabric | All gsm fabric |

| Special constructional fabric | All gsm fabric( Depends on target swatch) |

| All types of CVC fabric | All GSM (Which need polyester part dyeing) |

| Tightly knitted fabric | All Gsm fabric |

Setting parameter of this 100% heavy single jersey cotton fabric and result:

Temperature : 195’C

Over feed : 20%

Machine speed : 25

Padder pressure : 1st padder- 3, 2nd padder- 2

Ist batch liquid : Lubricant

2nd Batch Liquid : Lubricant

Before GSM : 263

After GSM : 256

| Setting parameter name | Before heat set | Setting In stenter machine | After heat set |

| Fabric diameter | 178 | 150 | 150 |

Loading to dyeing machine:

It is the 4th step of the dyeing process. Lubricant is injected into the machine for avoiding friction between the machine and the fabric surface. Then load the fabric. Cycle time, Pump pressure, Reel speed, Nozzle pressure setting controls here.

Scouring and Bleaching:

Normally scouring and bleaching are two different processes in oven fabric. But for knitting fabric, it is done in the same batch. For cotton fabric caustic soda and hydrogen peroxide uses for scouring and bleaching here.

Bio Polishing:

This is the process to remove the hairiness of the fabric surface. Bio polishing is done after the scouring and bleaching state. For special cases, it is also done after dyeing.

It is noted that excess dosing of enzymes can damage fabric strength.

Dyeing:

A reactive dyeing process is used here. This is one of the best sensitive fabrics (Heavy jersey). So that it needs special care to get better results. This is why we use a perfect dyeing process. The result of this fabric dyeing process is good to use. I am personally using this process in my factory for better results.

After-treatment:

In this stage, neutralization is done. Then the unfixed dyes are removed by a soaping agent. Better or high-temperature soaping will give you better fastness properties. But here the dye shade% is low. So that no need to high soaping. Here core neutralizer is used to get better results. But we can also use only ascetic acid for naturalization.

Special note For Cotton heavy jersey fabric: Need proper heat setting. Lubricant must have to inject before loading the fabric. The cycle time range will be 2min-3min(Not below 2min).

Dyeing Recipe of 100% cotton fabric:

Here I gave the chemical agent’s name. Because I am not sharing the original brand name. The dosing depends on the dyes and chemical supplier.

| Chemical Name | G/L |

| Detergent | 2.00 |

| Anti-creasing agent | 2.00 |

| Sequestering agent | 1.00 |

| Peroxide stabilizer | 2.00 |

| Caustic Soda | 2.00 |

| H2O2 | 1.00 |

| Peroxide killer | 0.15 |

| Acid (Neutralizing) | 0.7 |

| Leveling agent | 2.00 |

| Anti-creasing agent | 2.00 |

| Sequestering agent | 0.5 |

| Gold SE | 0.0160% |

| Lt Red SE | 0.0030% |

| lt Blue SE | 0.0018% |

| Salt | 20 |

| Soda Ash Lt | 5 |

| Acid (Neutralizing) | |

| Soaping Agent | 0.80 |

| Anti-creasing agent | 1.00 |

| Leveling agent | 2.00 |

| Acitic acid(cotrao ph 5) | 0.10 |

| Softener | 1.00 |

Dyeing process 100% cotton fabric step by step:

Color Name :

Batch quantity : 25kg

Dyeing Type : Reactive dyeing

M:L : 1: 7

Enzyme Type : Acid Enzyme

Cycle Time : 2.5 min

Special Note: Care full about the process. Careful about crease marks, long marks, uneven, etc.

Scouring & Bleaching

Detergent + Anti-creasing agent = Inject

Temp 40c*= Fabric Load

Caustic soda Dosing

Temperature 60c*20 Minute

Temperature 70c

Sequestering agent + H2O2 Dosing 5 Minute

Temp to 98’C & run 40 Minute

Cooling at 78’C

Sample check

If the sample ok then Drain

Normal Hot 70*10

Peroxide killer 60*10 Minute

Drain

Naturalization with acid

Drain

Wash 10 min

Dyeing

Leveling PH check 6.20

Leveling Dosing 60c 3 Minute

Color Dosing 30 Mints

Runtime 20 mint

Salt Dosing 10 Minute

Runtime 10 Minute

Salt Sample check + Fabric Quality Check

1st 1% Soda dosing 15 minute

Runtime 15 minute

2nd 99% % Soda dosing 20 minute

Runtime 20 minute

Sample check If ok then

Bath Drop

After Treatment

Soaping

Hot wash

Neutralizer

Drain wash

Soaping

Wash clear

Ph control 5

Softener

Unload

Finishing Process of 100% cotton heavy single jersey fabric:

Now we completed dyeing this fabric. Now we discuss the finishing process and parameter step by step below:

Finishing flow chart of cotton heavy single jersey fabric:

Short Description of the flow process stages for better understanding:

Slitting:

After knitting the fabric we get it as a tube format fabric. But we have to use an open stenter and compacting machine to get better results. So that the fabric needs to open. This is why we use this machine to open this fabric.

Setting parameter And result:

| Machine speed | 40 |

| Padder Pressure | 1.5 |

| Fabric In Diameter | 30 Cm (Tube) |

| Fabric Out Diameter | 150 Cm ( open) |

Stenter:

We dry the fabric and control the dia, GSM, and shrinkage. For this, we need to appropriate setting. I am giving the setting which I did for this batch

Setting parameter:

| Stenter Parameter | ||

| Setting | Speed | 16 |

| Dia | 155 | |

| Tem | 120 | |

| Overfeed | 59% | |

| Padder Pressure | 3+2 | |

| After Stenter | Dia | 152 |

| GSM | 253 | |

| Shrinkage | Length | |

| Width | ||

| Spirality |

Compacting:

Full dia, gsm, and shrinkage are controlled here. Better appearance and looking are done here. The overall quality of dyeing is controlled here.

I am giving the parameter which I did for the subjective batch.

| Compacting Parameter | ||||

| Common Setting | Overfeed | 35% | ||

| Speed/RPM | 14 | |||

| Temp | 120 | |||

| Steam Pressure | 30 | |||

| Topic | Target | Before | setting | after |

| Dia | 150 | 152 | 150 | 150 |

| Gsm | 280 | 253 | 264 | |

| Shrinkage | ||||

| Tumble dry | Length | -3% | ||

| Width | -6% | |||

| Spirality | 2% |

Now the fabric is sent to the testing lab for all the test reports.

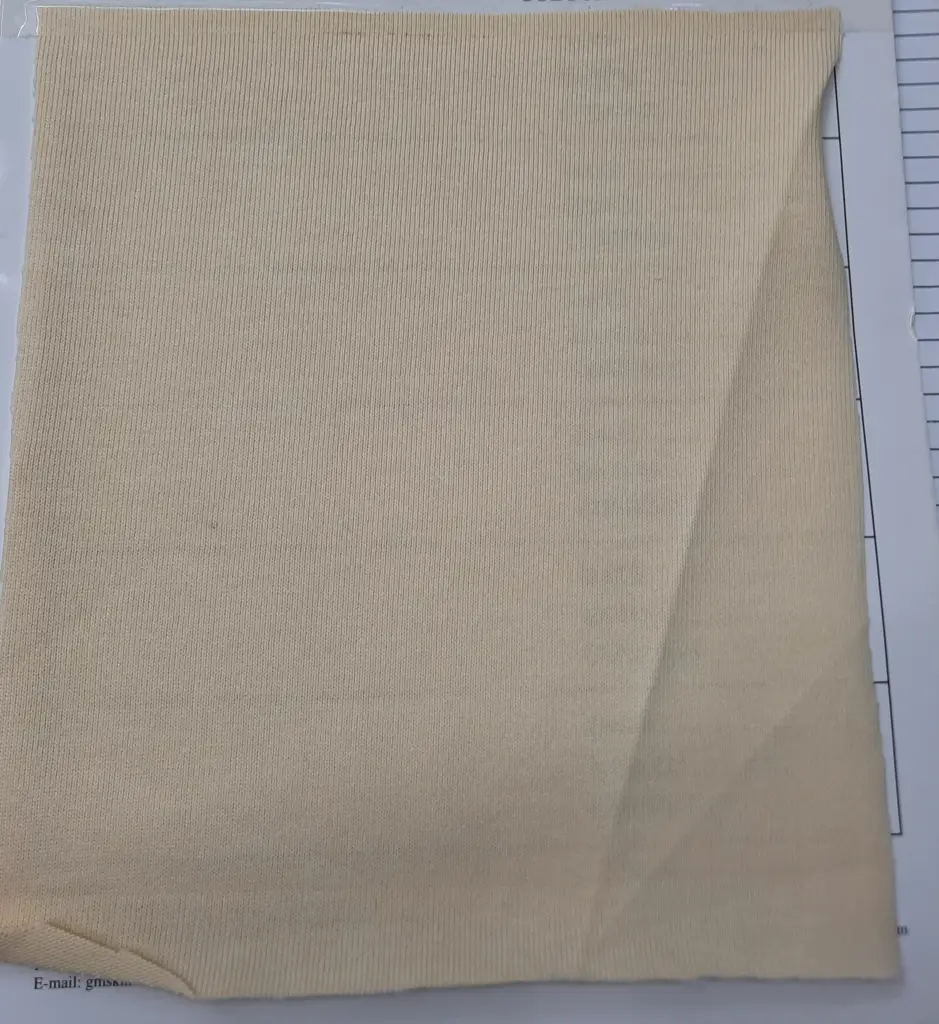

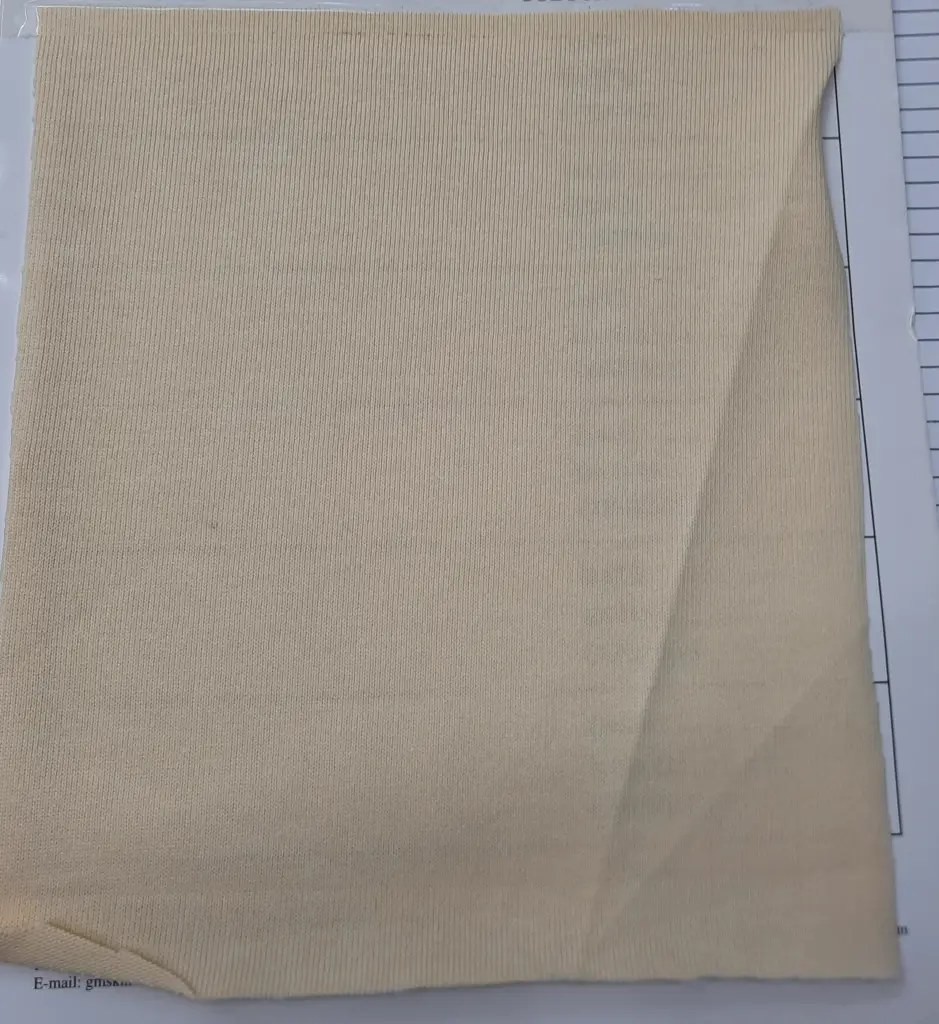

The Finished Fabric Picture of This Cotton Fabric Knitting Dyeing Process

The Testing Report of 100% Cotton Fabric:

How many Tests will be done on the fabric depending on the buyer’s requirement? This batch is done for development so the basic testing is done here. We did the test.

- Dimensional Stability To Washing

- Spirality After Washing

- Color Fastness to Washing

- Color Fastness to Rubbing

- Color Fastness to Water

- Color Fastness to Perspiration

- Color Fastness To Artificial Light

- Mass Per Unit Area

- Fiber Analysis

Knitting and dyeing Department: Practical Textile

Contact Person:

Eng. MK Islam

CEO of Practical Textile

Sample Detail:

Sample Submitted for Testing: 09 August 2021, Time:11:00am

Test Period: 09 August 2021 to 11 August 2021

Turn Around Time: 03 days

No Of Sample Received: Two (02) Meter

Sample Description & Color Name: Knitted of S/J Fabric Sample Marked as

Fiber Content 100% Cotton

Fabric Weight: 280 GSM

Care Ins

Test Program: Package Test

Buyer Name: Knitting and Dyeing development of Practical Textile

Conclusion of Test Results:

| Sl. No. | Test Name | Results (A) |

| 01 | Dimensional Stability To Washing | Pass |

| 02 | Spirality After Washing | Pass |

| 03 | Color Fastness to Washing | Pass |

| 04 | Color Fastness to Rubbing | Pass |

| 05 | Color Fastness to Water | Pass |

| 06 | Color Fastness to Perspiration | Pass |

| 07 | Color Fastness To Artificial Light | Pass |

| 08 | Mass Per Unit Area | Fail |

| 09 | Fiber Analysis | Pass |

TEST RESULTS DESCRIPTION

01. Dimensional Stability To Washing

Test Method: DIN EN ISO 6330:2012

Test Condition: Mild Program, Machine wash@40°C, Line Dry, Used Washing Machine Miele, 25-gram Arial Reference Detergent With 2.0kg Load.

| Sample (A) | After One Wash | |

| Direction | Result | Client Requirement |

| Length | -2.8% | ±4% |

| Width | +0.4% |

Remark: (+) Means Extension And (-) Means Shrinkage

02. Spirality After Washing

Test Method: ISO 16322-2;2005

Test Condition: Mild Program, Machine wash@40°C, Line Dry, Used Washing Machine Miele, 25-gram Arial Reference Detergent With 2.0kg Load.

| Sample (A) | Result (After One Wash) | Client Requirement |

| Spirality | 4.0% | 3% or 3cm |

03. Color Fastness To Washing

Test Method: DIN EN ISO 105 CO6-A1M

Test Condition: Temperature At 40ºC, Time 30 Min, Detergent 4gm/L ECE, Sodium Per Borate: 1g/l With 10 Pcs Steel Balls.

| Sample (A) | Result | Client Requirement |

| Color Change | 4 | 3-4 |

| Color Staining | 3-4 | |

| -Acetate | 4-5 | |

| -Cotton | 4-5 | |

| -Nylon | 4-5 | |

| -Polyester | 4-5 | |

| -Acrylic | 4-5 | |

| -Wool | 4-5 |

04. Color Fastness To Rubbing

Test Method: DIN EN ISO 105 X12 :2016

Test Stage: As Received Stage

| Sample (A) | Result | Client Requirement |

| Dry Rub | 4-5 | 3-4 |

| Wet Rub | 4-5 | 3 |

05. Color Fastness To Water

Test Method: DIN EN ISO 105 E01:2013

Test Condition: Temperature at 37±2ºC, Time 4 hours.

| Sample(A) | Result | Client Requirement |

| Color Change | 4-5 | 4-5 |

| Color staining | 4 | |

| -Acetate | 4-5 | |

| -Cotton | 4-5 | |

| -Nylon | 4-5 | |

| -Polyester | 4-5 | |

| -Acrylic | 4-5 | |

| -wool | 4-5 |

06. Color Fastness To Perspiration

Test Method: DIN EN ISO 105 E04:2013

Test Condition: Temperature At 37±2ºC, Time 4 Hours.

| Sample (A) | Result | Client Requirement | |

| Acid | Alkaline | ||

| Color Change | 4 | 4 | 3-4 |

| Color Staining | 3-4 | ||

| -Acetate | 4-5 | 4-5 | |

| -Cotton | 4-5 | 4-5 | |

| -Nylon | 4-5 | 4-5 | |

| -Polyester | 4-5 | 4-5 | |

| -Acrylic | 4-5 | 4-5 | |

| -Wool | 4-5 | 4-5 |

07. Color Fastness To Artificial Light

Test Method: DIN EN ISO 105 B02:2014, Air Cool Xenon, Arc Lamp.

| Result | Client Requirement | |

| Sample (A) | ||

| Up to Grade 4 (Blue wool scale) | 4 | 3-4 |

08. Mass Per Unit Area

Test Method: ISO 3801: 1977,Method 5

Test Stage: As Received Stage

| Sample(A) | Result | Client Requirement |

| Average | 252.2 g/m2 | 280 g/m2(±5%) |

09. Fiber Analysis

Test Method: ISO 1833:2006

Test Condition: As Received Stage

| Sample (A) | Result | Client Requirement | |

| Identification of fibers | Cotton | +3% to -3% | |

| Analyzed fibers | Cotton | 100% | 100% Cotton |

| Note: Based On Moisture Regain Value According To Regulation ( EU ) No 1007/2011 | |||

Overall Comments on the 100% cotton fabric knitting and dyeing process:

After analyzing all the test reports I can say that the GSM of the fabric is low. Normally we tolerate +/- 5%. Bet here we get -10%. This is not in an acceptable range.

Solution: There are many ways to solve the problem.

First, we can Re compacting the fabric with the setting

Over feed= 50%

Diameter setting = 145cm

I think it will give better results. But must you have to think about shrinkage?

Secondly, we can change the yarn count to get the required result.

Conclusion:

I am sharing here my full cotton fabric knitting and dying process with a flow chart. A complete practical Gide line is available here. Of course, everyone can ask me any process-related questions in the comment section. I will answer the entire question. As a textile engineer, I think I can solve problems from my 10 years of practical experience.

Research Link:

You may read some other articles

- Fleece Fabric || Dyeing, Finishing, and Testing Of 100% Cotton Fleece Fabric With A Complete Practical Experiment

- 100% cotton crepe single jersey fabric dyeing and finishing process with a complete practical experiment

- What Is Cotton Interlock knit fabric? It’s Knitting, Dyeing, Finishing Development.

- Knitted Fabric Quality Control Parameters

[…] 100% Cotton Fabric Knitting Dyeing Process (Reactive dye), Flow Chart With Complete Practical Docume… […]

[…] 100% Cotton Fabric Knitting Dyeing Process (Reactive dye), Flow Chart With Complete Practical Docume… […]