Printing in garments refers to the technique of applying designs, patterns, or images onto fabric surfaces. This process enhances the aesthetic appeal of the garment. Also used to convey a specific message or branding. There are different types of printing methods for garments are available.

In the vibrant world of garment manufacturing, the art of printing plays a crucial role in bringing designs to life on fabric. With a myriad of techniques at their disposal, garment manufacturers can achieve diverse and captivating visuals to meet the demands of ever-evolving fashion trends and consumer preferences. From traditional methods passed down through generations to cutting-edge digital innovations, the array of printing methods in the garment industry is as diverse as the fabrics they adorn. In this exploration, we delve into the fascinating realm of garment printing, uncovering the various types of printing methods that fuel creativity, enable customization, and shape the landscape of fashion production.

Top 9 Most Useign Types of Printing Methods for Garments

There are several types of printing methods used in the garment industry to apply designs, patterns, or images onto fabric. Some of the common printing methods include:

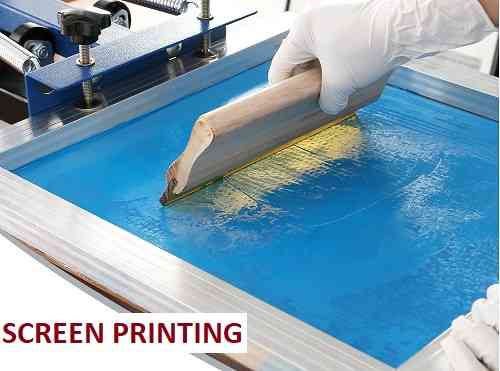

Screen Printing:

This is one of the oldest and most widely used methods. It involves creating a stencil (screen) for each color in the design and then pushing ink through the screens onto the fabric.

Screen printing, also known as silk screening. This a printing technique where a mesh screen is used to transfer ink onto a substrate, such as paper, fabric, metal, or plastic. It’s a versatile printing method suitable for various materials. This method is commonly used in the production of garments, posters, labels, decals, signage, and more.

Here’s a basic overview of the screen printing process:

In screen printing, the process starts by creating or preparing the design. This can be done digitally using software like Adobe Illustrator or by hand for intricate designs.

Next, a mesh screen made of fabric is stretched tightly over a frame. The screen is coated with a light-sensitive emulsion.

The prepared design is then transferred onto a transparent film or acetate. This film is placed on top of the coated screen, and the entire setup is exposed to light. The light hardens the emulsion where the design is, leaving the rest of the emulsion soft and washable.

After exposure, the screen is washed with water, removing the soft, unexposed emulsion, and leaving a stencil of the design on the screen.

The prepared screen is mounted onto a printing press. Ink is applied to the screen and spread evenly over the design area using a squeegee. The ink passes through the mesh screen onto the substrate below, transferring the design.

Once printing is complete, the ink needs to be cured or dried. This can be done using heat or UV light, depending on the type of ink and substrate material.

For multi-color designs, the process is repeated with additional screens, each carrying a different color of ink. Proper registration is crucial to ensure each color lines up correctly.

Screen printing offers several advantages, including:

- Durability: Screen-printed designs tend to be more durable and long-lasting compared to other printing methods.

- Versatility: It can be used on a wide range of substrates, including textiles, plastics, glass, and metals.

- Vibrant Colors: Screen printing allows for vibrant and opaque colors, making it ideal for designs that require high color saturation.

- Cost-Effectiveness: For large production runs, screen printing can be more cost-effective than other methods, particularly when printing in bulk.

However, screen printing also has some limitations, such as being less suitable for intricate designs with fine details and gradients compared to digital printing methods like DTG (Direct-to-Garment) printing. Additionally, setting up screens for each color can be time-consuming and costly for small print runs.

Digital Printing:

This method involves printing the design directly onto the fabric using inkjet printers. It’s suitable for intricate designs and allows for easy customization.

Digital printing refers to a modern printing method that involves transferring digital-based images directly onto a variety of substrates. Unlike traditional printing methods such as offset or screen printing, which require the creation of plates or screens, digital printing relies on computer-controlled printers to reproduce the desired image.

Here’s an overview of the digital printing process:

- Design Preparation: The process begins with creating or preparing the design digitally using graphic design software such as Adobe Photoshop or Illustrator. The design is typically saved in a digital file format such as JPEG, PNG, or PDF.

- Printing: The digital file is sent directly to the digital printer, which recreates the image onto the chosen substrate. Digital printers use various technologies such as inkjet or laser to apply ink or toner onto the surface of the substrate.

- Curing/Fixing: Depending on the type of printer and ink/toner used, curing or fixing may be required to ensure the printed image adheres properly to the substrate and achieves the desired durability. This can involve heat curing, UV curing, or chemical fixing processes.

Digital printing offers several advantages compared to traditional printing methods:

- Quick Turnaround: Digital printing eliminates the need for time-consuming setup processes like plate or screen creation, allowing for quicker turnaround times, and making it ideal for on-demand or short-run printing jobs.

- Variable Data Printing: Digital printing enables the customization of each printed piece, allowing for variable data printing, such as personalized text, images, or graphics. This is particularly useful for applications like direct mail campaigns, personalized marketing materials, and product packaging.

- High-Quality Output: Digital printing technology has advanced significantly in recent years, allowing for high-resolution, photo-quality prints with vibrant colors and fine details.

- Cost-Effectiveness for Small Runs: Since there are no setup costs associated with digital printing, it can be more cost-effective for small print runs compared to traditional printing methods like offset or screen printing.

- Environmentally Friendly: Digital printing produces less waste compared to traditional printing methods since it doesn’t require the creation of plates or screens. It also consumes fewer resources such as ink and paper, making it more environmentally friendly.

However, digital printing also has some limitations:

- Limited Substrate Compatibility: Digital printing may not be suitable for all types of substrates, particularly those with unusual textures or surfaces. Additionally, certain digital printing technologies may have limitations on the types of substrates they can print on.

- Higher Cost per Page for Large Runs: While digital printing can be cost-effective for small print runs, the cost per page may be higher for large production runs compared to traditional printing methods like offset printing.

Overall, digital printing offers flexibility, customization, and high-quality output, making it a popular choice for a wide range of printing applications, including marketing materials, labels, packaging, signage, and more.

Heat Transfer Printing:

In this method, designs are printed onto a special transfer paper using inkjet or laser printers. The paper is then placed on the fabric and heat is applied to transfer the design onto the fabric.

Heat transfer printing is a method used to apply designs or images onto a substrate. Typically fabric, using heat and pressure. Here’s a concise overview:

- Design Preparation: Designs are digitally created or obtained, then printed onto special transfer paper using sublimation inks or pigment inks.

- Transfer Process: The printed design is placed face-down onto the substrate. Then heat and pressure are applied using a heat press machine. This causes the ink on the transfer paper to sublimate or adhere to the surface of the substrate.

- Cooling and Finishing: After a set time, the heat is removed. Then transfer paper is peeled away, leaving the design permanently bonded to the substrate.

Heat transfer printing is popular for customizing garments like T-shirts and jerseys. As well as producing promotional items such as mugs and mouse pads. It offers versatility in applying full-color designs and photographic images onto various materials. However, the durability of heat transfer prints may vary based on factors like substrate type and laundering conditions.

Sublimation Printing:

Sublimation printing involves transferring designs onto special paper with sublimation inks. Then, these designs are transferred onto the fabric using heat and pressure. This method is commonly used for polyester fabrics.

In sublimation printing, designs are digitally created or obtained and printed onto special transfer paper using sublimation inks. The printed design is then placed onto the substrate, and heat and pressure are applied using a heat press machine. This causes the sublimation inks to convert into a gas without passing through the liquid phase, bonding directly with the substrate’s surface. After the transfer process, the substrate is allowed to cool, and the transfer paper is removed, leaving the design permanently embedded into the substrate.

Sublimation printing offers vibrant, high-resolution prints with excellent color reproduction and durability, especially on polyester fabrics. It is commonly used for creating custom apparel, promotional products, personalized gifts, and photo merchandise. However, sublimation printing is limited to substrates with a polyester or polymer coating, as these materials can absorb the sublimation inks.

Rotary Printing:

This method is used for high-volume production. It involves printing designs onto fabric using cylindrical rollers engraved with the design. Each roller applies a different color, allowing for complex multicolor designs.

Rotary printing is a high-speed printing technique used primarily in textile printing. Here’s a concise overview:

- Rotary Screen Printing: In rotary printing, cylindrical screens are used instead of flat screens or plates. These screens have a continuous pattern or design engraved or etched onto their surface.

- Ink Application: The screens rotate continuously, and ink is applied to the screens as they rotate. The ink is forced through the screen’s mesh onto the substrate (fabric) below.

- Printing Process: The fabric moves beneath the rotating screens, allowing for continuous and seamless printing of the design onto the fabric.

- Drying and Fixing: After printing, the fabric passes through drying and fixing units to cure the ink and ensure it adheres permanently to the fabric.

Rotary printing offers several advantages, including high-speed production, precise registration, and the ability to print intricate designs with fine details. It’s commonly used in the textile industry for printing patterns, designs, and colors onto fabrics for clothing, upholstery, bedding, and other textile products. However, rotary printing requires significant setup and maintenance of the rotary screens, making it more suitable for large-scale production runs.

Block Printing:

This is a traditional method where designs are carved onto wooden blocks, which are then dipped in ink and stamped onto the fabric.

Block printing is a traditional form of printing where a design is carved into a block of material, such as wood, linoleum, or rubber. Here’s a brief overview of the process:

- Design Creation: A design is drawn or transferred onto the surface of the block.

- Block Carving: Skilled artisans use carving tools to cut away the areas of the block that are not part of the design, leaving a raised surface with the design in relief.

- Ink Application: Ink or dye is applied to the raised surface of the block using a roller or brush. The block is inked evenly to ensure uniform coverage.

- Printing: The inked block is pressed firmly onto the substrate, such as paper or fabric, transferring the design onto the surface. Pressure may be applied by hand or through the use of a press.

- Repeat: The process is repeated for each impression, with the block being re-inked for each print.

Block printing is known for its simplicity and versatility. It allows for the creation of unique, handcrafted prints with a characteristic handmade feel. It is widely used in textile printing for creating patterns on fabrics, as well as in printmaking for producing artwork on paper. Additionally, block printing techniques vary across different cultures and regions, resulting in a rich diversity of styles and traditions.

Foam Printing:

In this method, a foam paste is applied to the fabric in the desired design using screens. The fabric is then dyed, and the foam area resists the dye, creating the pattern.

Foam printing, also known as foam block printing, is a creative and accessible form of printmaking suitable for both children and adults.

Here’s a concise explanation:

- Materials Preparation: Foam sheets are commonly used for this technique due to their softness and ease of carving. Other materials such as foam boards or even styrofoam can also be used. A flat, smooth surface for printing and water-based printing ink or paint are also needed.

- Design Creation: Using a pencil, a design is drawn or traced onto the foam sheet. Simple designs with bold lines work best for foam printing.

- Carving: Using a ballpoint pen or a special foam carving tool, the design is carefully carved into the foam sheet. The carved areas will not pick up ink, leaving the raised areas to transfer the design onto the printing surface.

- Ink Application: Ink or paint is applied onto the raised surface of the foam block using a roller, brush, or foam brush. The ink should be evenly distributed over the surface of the block.

- Printing: The inked foam block is pressed firmly onto the printing surface, such as paper or fabric, transferring the design onto the surface. Pressure may be applied by hand or through the use of a press.

- Repeat: The process can be repeated to create multiple prints with the same design.

Discharge Printing:

This process involves applying a chemical to dyed fabric, which removes the dye and leaves a lighter area in the desired design.

Discharge printing is a specialized method used in textile printing to create designs on fabrics, particularly cotton or other natural fibers.

Here’s an overview of the process:

- Chemical Application: A discharge paste or ink containing a discharge agent is applied to the fabric in the desired design areas. The discharge agent works by breaking down or removing the existing color from the fabric.

- Printing: The fabric is then screen printed with the discharge paste or ink, covering the designated areas with the discharge agent.

- Activation: The printed fabric is exposed to heat, typically through a heat press or conveyor dryer, which activates the discharge agent.

- Color Removal: As the discharge agent is activated by heat, it chemically reacts with the dye or pigment in the fabric, effectively removing or neutralizing the color from those areas. This process leaves the fabric with a bleached or lighter-colored design against the original fabric color.

- Washing and Finishing: After printing and activation, the fabric is washed to remove any remaining discharge paste or ink, as well as any residues from the discharged color. The fabric may then undergo additional finishing processes, such as drying and ironing.

Discharge printing offers several advantages, including:

- Soft Hand Feel: Since the design is created by removing color from the fabric rather than adding additional layers of ink or pigment, discharge prints often have a soft hand feel.

- High Detail: Discharge printing can achieve intricate and detailed designs with sharp edges and fine lines.

- Tonal Range: By adjusting the type and concentration of discharge agents used, a wide range of tones and shades can be achieved, from subtle pastels to bold contrasts.

However, there are also some limitations to consider:

- Limited Color Range: Discharge printing works best on fabrics that contain reactive dyes, which are commonly used in cotton fabrics. It may not be as effective on fabrics dyed with certain types of pigments or synthetic dyes.

- Environmental Considerations: Some discharge agents contain chemicals that can be harmful to the environment if not properly managed. It’s important to follow proper handling and disposal procedures to minimize environmental impact.

- Complex Process: Discharge printing requires careful control of various factors such as ink formulation, fabric composition, and curing conditions, which can make it more challenging and time-consuming compared to other printing methods.

Overall, discharge printing is valued for its ability to create unique and high-quality designs with a soft feel, making it a popular choice for producing premium textile products such as fashion apparel, home furnishings, and specialty garments.

Flock Printing:

Flock printing involves applying adhesive and tiny fibers (flock) onto the fabric to create a textured design. The adhesive is printed onto the fabric, and then the flock is applied using electrostatic charges, resulting in a velvety, raised surface with a soft touch.

Flock printing is a specialized textile printing technique that involves applying a layer of adhesive to a fabric substrate and then coating it with tiny fibers, known as flock, to create a soft, velvety texture.

Here’s how the process typically works:

- Design Preparation: A design is created, often using vector graphics software, and then converted into a stencil or template.

- Adhesive Application: The fabric substrate is coated with a layer of adhesive in the shape of the desired design using a screen printing technique or a specialized flock printing machine. The adhesive is typically applied using a fine mesh screen or a roller.

- Flock Application: While the adhesive is still wet, flock fibers are sprinkled or electrostatically applied onto the adhesive-coated areas. The flock fibers adhere to the adhesive, forming the raised, velvety design.

- Curing: The printed fabric is then passed through a heat curing process, which activates the adhesive and ensures that the flock fibers are securely bonded to the fabric.

- Finishing: After curing, the fabric may undergo additional finishing processes, such as brushing or steaming, to remove excess flock fibers and enhance the softness and appearance of the printed design.

Flock printing offers several advantages, including:

- Textured Finish: Flock printing creates a luxurious, tactile finish with a soft, velvety feel that adds depth and dimension to the printed design.

- Durability: Flock prints are durable and resistant to fading, making them suitable for a wide range of applications, including apparel, accessories, and upholstery.

- High Contrast: Flock printing allows for high-contrast designs with sharp, defined edges, making it ideal for bold, graphic motifs and lettering.

However, there are also some limitations to consider:

- Limited Color Range: Flock printing is typically done using a single color of flock fibers, so achieving multi-color designs may require additional printing and flocking steps.

- Complexity: Flock printing can be a more complex and time-consuming process compared to other textile printing techniques, requiring precise control of adhesive application and flocking conditions.

- Cost: Flock printing may be more expensive than other printing methods due to the specialized materials and equipment required.

Overall, flock printing is valued for its unique texture and tactile appeal, making it a popular choice for adding decorative accents and embellishments to a variety of textile products.

These are just some of the common printing methods used in the garment industry, each with its own advantages and limitations depending on the desired design, fabric, and production requirements.

Other 13 printing types are also used in garments

Here’s a detailed description of each topic:

Roller Printing:

Roller printing utilizes cylindrical rollers engraved with the desired design. As the fabric passes between the rollers and a printing table, the design is transferred onto the fabric. It’s a high-speed and cost-effective method commonly used for large-scale production of patterned fabrics.

Dye-sublimation Printing:

Dye-sublimation printing involves transferring dye onto fabric using heat and pressure. The dye is sublimated from a solid to a gas state without passing through a liquid state, resulting in vibrant and permanent prints. This method is particularly suitable for polyester fabrics.

Pigment Printing:

Pigment printing involves applying pigments directly onto the fabric surface using a binder. The pigments adhere to the fabric fibers, creating a durable and colorfast print. Pigment printing is known for its versatility and suitability for a wide range of fabric types.

Direct Printing:

Direct printing, also known as wet-on-wet printing, involves applying dyes or pigments directly onto the fabric surface. This method is suitable for both natural and synthetic fibers and allows for intricate designs with a high level of detail.

Digital Fabric Printing:

Digital fabric printing is a subset of digital printing specifically focused on printing designs onto fabric. It allows for customization, rapid prototyping, and on-demand production, making it a popular choice for small-scale textile manufacturers and designers.

Reactive Printing:

Reactive printing involves using reactive dyes that chemically bond with the fabric fibers to create vibrant and permanent prints. This method is especially suitable for natural fibers like cotton and linen, offering excellent colorfastness and wash durability.

Resist Printing:

Resist printing involves applying a resist substance onto fabric to create patterns or designs that resist subsequent dyeing or printing processes. The resist can be applied using various techniques such as wax, starch, or chemicals, resulting in intricate and unique designs.

Spray Printing:

Spray printing involves spraying dyes or pigments onto fabric using handheld or automated spray guns. It offers flexibility in creating gradients, patterns, and artistic effects, making it popular for experimental and artistic applications.

Stamp Printing:

Stamp printing, also known as block printing, involves manually applying ink or dye onto fabric using carved stamps or blocks. It’s a simple and versatile method suitable for small-scale production and DIY projects.

Stencil Printing:

Stencil printing involves creating a stencil (or template) with the desired design and then applying ink or dye through the stencil onto fabric. It allows for precise and repeatable designs and is commonly used for screen printing and hand-painting techniques.

Warp Printing:

Warp printing is a specialized method where the warp yarns are printed with the desired design before weaving. This allows for intricate patterns and designs to be woven directly into the fabric during the weaving process.

Carpet Printing:

Carpet printing is a specialized form of textile printing used to create patterned designs on carpets and rugs. It typically involves techniques such as screen printing, digital printing, or roller printing to apply colors and patterns onto the carpet surface.

Foil Printing:

Foil printing involves applying a metallic foil onto fabric using heat and pressure. The foil adheres to the fabric surface, creating a shiny and reflective design. It’s commonly used for adding decorative accents and embellishments to garments and textiles.

These are the most common printing methods used all over the world.

Some related topics and FAQs about printing you should know:

Adequate Quality Control Flow Chart Of Placement Print: Adequate quality control for placement print involves a systematic process to ensure that printed designs are accurately positioned on garments according to specifications. The quality control flow chart typically includes steps such as initial inspection, verifying design specifications, visual inspection, measurement checks, color consistency checks, placement accuracy checks, surface inspection, labeling and documentation, decision-making regarding rejection or rework, and final inspection before packaging and shipping. This ensures that garments meet the required standards of quality and consistency in print placement.

Are Acrylic And Fabric Paint the Same: Acrylic paint and fabric paint are both used for artistic endeavors, but they differ in composition and application. Acrylic paint, made with pigments suspended in acrylic polymer emulsion, is versatile and can be used on various surfaces, including fabric.

Will Fabric Paint Work on Wood: Yes, fabric paint will work on wood. You will need to use a primer first, then paint your design with fabric paint. The key is to make sure the primer and paint are both meant for use on fabric. Fabric paint, renowned for its versatility in textiles, raises questions about its applicability to other surfaces like wood. While fabric paint is specifically formulated for fabric fibers, its effectiveness on wood depends on factors like adhesion and durability.

Best Paint For Handprints On Fabric For Kids For kids’ handprints on fabric, opt for non-toxic, washable fabric paints. These paints are safe, easy to use, and offer vibrant colors. Look for water-based options for quick drying and mess-free fun!

Will Fabric Paint Wash off Clothes Yes, fabric paint will wash off clothes. However, the amount of time it takes for the paint to come off will vary depending on the type of fabric and the type of paint used. For example, if you use water-based paint on a natural fiber like cotton, the paint will likely come off in the …

Will Fabric Paint Stick to Wood: Yes, fabric paint will stick to wood. You can either use a brush or a spray bottle to apply the paint. Make sure to sand the wood first so that the paint will adhere better. Are you looking for a way to add some color to your wood projects? Fabric paint is a great option! …

Will Fabric Paint Work on Leather: No, fabric paint will not work on leather. Leather is a tricky surface to paint. It’s different than painting fabric, wood, or even glass. But with the right preparation and products, you can successfully paint leather! Here are a few tips to get you started: – Choose an acrylic paint specifically made for leather. These …

Will Fabric Paint Stick to Vinyl: To answer this question, it is necessary to know what type of vinyl fabric you are trying to paint. If the vinyl is made of polyvinyl chloride (PVC), then fabric paint will not stick to it. This is because PVC is non-porous and therefore does not absorb paint the way that other fabrics do. However, …

Will Fabric Paint Work on Canvas: Yes, fabric paint will work on canvas. Canvas is a sturdy fabric that is often used for paintings and other art projects. Fabric paint is designed to adhere to fabric and will not damage the canvas. There are a lot of different types of fabric paint out there, so it can be tough to know-

Will Fabric Paint Work on Rocks: Yes, fabric paint will work on rocks. You can use a brush or sponge to apply the paint to the rock surface. The key is to make sure the rock is clean and dry before you start painting. If you’re looking for a fun and easy way to add some color to your rocks, fabric …

Can Fabric Paint Be Mixed With Water: Yes, fabric paint can be mixed with water. This can be done to thin the paint or to create a different effect. When mixing fabric paint with water, it is important to use a ratio of 1 part paint to 3 parts water. If you’re looking to add a little extra color to your crafting …

Can Fabric Paint Be Diluted With Water: Yes, fabric paint can be diluted with water. The amount of water you add will affect the opacity and thickness of the paint, so experiment to find the right consistency for your project. When diluting fabric paint with water, it’s best to use distilled water to prevent any impurities from affecting the paint color or …

Are Puffy Paint And Fabric Paint the Same: Puffy paint and fabric paint are not the same. Puffy paint is a type of painting medium that contains a gas that causes it to expand when it dries, creating a raised effect. Fabric paint, on the other hand, is a type of paint that is specifically designed to be used on fabric. It is …

Are Fabric Colours And Acrylic Paint the Same?: No, fabric colors and acrylic paint are not the same. Fabric colors are made specifically for fabrics and therefore will not work as well on other surfaces. Acrylic paint is versatile and can be used on a variety of surfaces, but it may not adhere to fabric as well as a specific …

Will Fabric Paint Stick to Metal?: Yes, fabric paint will stick to metal. You can use a brush or a sponge to apply the paint to the metal surface. Fabric paint is available in a variety of colors and can be used to create different designs on your metal project. BEST PAINT FOR HAND PAINT If you’re looking to add a …

Will Fabric Paint Stick to Silicone: Yes, fabric paint will stick to silicone. You may need to prime the surface first with white acrylic paint to get good coverage. BEST PAINT FOR HAND PAINT It’s a common question – can fabric paint stick to silicone? The answer is yes, but there are a few things you need to know before …

Will Fabric Paint Stick to Leather: Yes, fabric paint will stick to leather. However, it is important to note that the paint may not adhere as well to smooth leather surfaces. To increase the chances of the paint adhering, roughen the surface of the leather beforehand with sandpaper. In addition, be sure to use a fabric paint that is specifically made …

Will Fabric Paint Stick to Glass: Yes, fabric paint will stick to glass. You can use any type of fabric paint, but you may need to thin it out a bit with water so that it doesn’t clump up on the glass. Also, make sure to clean the glass surface well before painting so that the paint will adhere better. Whether …

Will Fabric Paint Stick to a Pumpkin: Yes, fabric paint will stick to a pumpkin. However, it is important to note that not all fabrics are created equal and some may be more difficult to work with than others. In addition, the type of paint you use may also affect how well it adheres to the pumpkin’s surface. If you’re looking for …

Will Fabric Paint Work on Pumpkins: Yes, fabric paint will work on pumpkins. You can use any kind of fabric paint, but you might want to use one that is specifically made for pumpkin painting. To prepare the pumpkin, you will need to clean it and then remove the top layer of skin. Once the pumpkin is prepared, you can start …

Will Fabric Paint Work on Plastic: Yes, fabric paint will work on plastic. The paint will adhere to the surface of the plastic and can be used to create a variety of designs. If you’re looking for a way to add some color to your plastic items, fabric paint is a great option! You can find fabric paint at most craft …

Will Fabric Paint Work on Metal: Yes, fabric paint will work on metal. You will need to prime the metal first with a spray primer designed for use on metal surfaces. Once the primer is dry, you can apply your fabric paint just as you would to any other surface. BEST PAINT FOR HAND PAINT Have you ever had a project …

Will Fabric Paint Work on Glass: Yes, fabric paint will work on glass. The key is to make sure that the glass is clean and dry before you start painting. Once the glass is dry, you can apply the fabric paint just like you would any other type of paint. Just be sure to let the paint dry completely before using …

Will Fabric Paint Wash off Hands?: Yes, fabric paint will wash off hands. However, it may take multiple washes to remove all of the paint. To avoid staining your skin, it is best to wear gloves when painting with fabric paint. If you’re looking for a way to add some color to your fabric projects, fabric paint is a great option! …

How Many Washes Does Fabric Paint Last: Fabric paint will last through many washes, though the number of washes may vary depending on the type and quality of fabric paint. Some fabric paints are made to be more durable than others, so it is important to check the product label before purchasing. Generally, high-quality fabric paints will withstand 20 or more washes …

How Long is Fabric Paint Good for: Fabric paint is typically good for about 2-3 years. After that, the color may start to fade and the paint may become less effective. BEST PAINT FOR HAND PAINT If you’ve ever wondered how long fabric paint is good for, wonder no more! We’ve got the answer for you. It turns out that fabric paint …

How Long Does Puffy Fabric Paint Take to Dry: Puffy fabric paint will take approximately 24 hours to dry. However, it is recommended that you allow the paint to dry for 48 hours before washing the item. BEST PAINT FOR HAND PAINT Puffy fabric paint is a great way to add some dimension and interest to your fabric projects. But how long does it …

How Long Does Fabric Paint Need to Dry: Acrylic paint will dry to the touch within 15 minutes, but it can take up to 24 hours for the paint to fully cure. BEST PAINT FOR HAND PAINT When it comes to fabric paint, there is no one-size-fits-all answer to the question of how long it needs to dry. The type of fabric you …

How Fast Does Fabric Paint Dry: Acrylic paint will dry the fastest out of all the fabric paints. It can take as little as 15 minutes for the paint to be completely dry. BEST PAINT FOR HAND PAINT Whether you’re looking to add a pop of color to your wardrobe or personalize a gift, fabric paint is a great way to …

How Long Does Fabric Puffy Paint Take to Dry: Puffy paint is a type of fabric paint that can be used to create 3-dimensional designs on fabric. It is available in a variety of colors and can be applied with a brush or squeeze bottle. Puffy paint is made from a combination of acrylic paint and vinyl, so it is flexible and durable once …

Is Fabric Paint Good for Shoes: There is no definitive answer to this question as it depends on the specific fabric paint and the type of shoes. Some fabric paints may be good for shoes, while others may not be as effective. It is important to read the instructions on the fabric paint before using it on shoes. BEST PAINT FOR …

Will Fabric Paint Stick to Rubber: Yes, fabric paint will stick to rubber. It is important to clean the surface of the rubber before painting it with a mild soap and water solution. Once the surface is dry, you can apply the fabric paint directly to it. BEST PAINT FOR HAND PAINT One of the most frequently asked questions we get …

Will Fabric Paint Stick to Polyester?: Yes, fabric paint will stick to polyester. You may need to use a primer or heat set the paint to make it adhere properly. BEST PAINT FOR HAND PAINT Whether you’re looking to add a pop of color to your wardrobe or give a handmade gift a personal touch, fabric paint is a great way …

Will Fabric Paint Stick to Plastic?: Yes, fabric paint will stick to plastic. You’ll need to clean the plastic surface first and then rough it up a bit so that the paint can adhere. Once you’ve done that, you can apply the paint just as you would to any other surface. BEST PAINT FOR HAND PAINT Yes! You can most definitely …

How Do You Paint Fabric Without It Getting Stiff: You can paint fabric without it getting stiff by using a fabric medium. A fabric medium is a liquid that you mix with your paint to make it easier to work with and less likely to crack or peel. You can buy fabric medium at most craft stores, or you can make your own by …

How Do I Use Fabric Paint: Fabric paint is a type of paint that is specifically designed for use on fabric. It is usually made from a water-based acrylic paint, which makes it safe and easy to use. Fabric paint can be applied directly to the fabric using a brush or sponge, or it can be used to create designs by …

How Do You Use Fabric Paint: To use fabric paint, start by prepping your fabric by washing it and letting it dry. Then, create a design on paper or directly on the fabric. Once you’re happy with your design, trace it onto the fabric with a pencil. Next, start painting in your design using fabric paint and a brush. Finally, let …

How Do I Make Fabric Paint: You can make fabric paint by mixing a few simple ingredients. You will need: 1 cup of acrylic paint, 1/4 cup of fabric medium, and 1 tablespoon of distilled water. Mix all of the ingredients until they are well combined. Then, use a brush to apply the paint to your fabric. Let the …

Heat Transfer Vinyl on Painted Canvas: If you want to use heat transfer vinyl (HTV) on a painted canvas, you’ll need to make sure the paint is fully cured first. HTV won’t stick to fresh paint, so you’ll need to wait at least 2-3 weeks for the paint to cure before applying your vinyl. Once the paint is cured, you can …

Heat Set Fabric Paint Without Iron: To heat set fabric paint without an iron, you can use a hair dryer on the hottest setting. Hold the dryer about six inches away from the painted fabric and move it around constantly until the paint is dry to the touch. You can also place the fabric in a clothes dryer on the highest …

Fabric Spray Paint With Uv Protection: The best fabric spray paint with UV protection is the one that contains a high percentage of UV blockers. These paints work by absorbing or reflecting ultraviolet rays from the sun, preventing them from reaching the fabric beneath. They are typically applied as a topcoat over another type of paint, such as acrylic or …

How Do You Remove Fabric Paint: To remove fabric paint, first scrape off as much of the paint as possible with a blunt knife. Next, soak the stained fabric in warm water for 30 minutes. Then, apply a pre-wash stain remover to the affected area and launder the item according to the manufacturer’s instructions. If the stain remains, repeat these steps …

Heat Setting Acrylic Paint on Fabric: To heat set acrylic paint on fabric, you will need to use a hot iron. Place the fabric with the painted design on an ironing board. Cover the design with a thin piece of cloth. Iron the back of the fabric on a medium-high setting for 3-5 minutes, moving the iron around to avoid scorching …

How Much Fabric Paint Do I Need: Assuming you are painting on fabric, the amount of paint you will need will depend on the size of the project and the type of paint. If you are using a brush to apply the paint, you will need less than if you are using a spray bottle. Generally speaking, one 4-ounce bottle of fabric …

Does Fabric Spray Paint Wash off: Yes, fabric spray paint will wash off. However, it is important to note that the paint may fade or discolor after being washed. BEST PAINT FOR HAND PAINT Spray painting your fabric can be a great way to add color and pattern to your wardrobe. But does fabric spray paint wash off? The short answer …

Does Fabric Paint Work on Rubber: Yes, fabric paint does work on rubber. You will need to use a primer first and then apply the paint. It is important to make sure that the surface is clean and smooth before you begin painting. BEST PAINT FOR HAND PAINT If you’re looking for a way to add some color to your rubber …

Does Fabric Paint Work on Polyester: Yes, fabric paint does work on polyester. You may need to use a primer first, however, to help the paint adhere better. When painting on polyester, it’s also important to use thin layers of paint and allow each layer to dry completely before adding more. With proper preparation and care, you can successfully add fabric …

Does Fabric Paint Work on Plastic: Yes, fabric paint does work on plastic. The paint will adhere to the surface of the plastic and will not easily come off. You can use fabric paint to create a variety of designs on your plastic surfaces. BEST PAINT FOR HAND PAINT If you’re looking for a way to add some color to your …

Dupli Color Vinyl Fabric Paint Yellow: Dupli-Color® Vinyl & Fabric Coating is perfect for restoring or customizing your interior vinyl seats, dashboards, door panels, shifter boots, and consoles. Dupli-Color® Vinyl & Fabric Coating won’t crack, peel or chip. BEST PAINT FOR HAND PAINT Looking for a way to add some extra pizzazz to your car’s interior? Consider Dupli Color’s Vinyl …

Does Fabric Paint Work on Rocks: Yes, fabric paint will work on rocks. The key is to make sure that the rock is clean and dry before you start painting. Once the rock is painted, you can seal it with a clear sealer to help protect the paint. BEST PAINT FOR HAND PAINT If you’re looking for a fun and easy …

Fabric Spray Paint for 100 Polyester: There are a few brands that make fabric spray paint that is safe for 100% polyester fabrics. You will want to look for a brand that specifically says it is safe for polyester and follow the instructions on the can. Make sure you test a small area first to see how the paint reacts with …

Fabric Spray Paint Duck Egg Blue: Duck Egg Blue is a beautiful, light blue color. It’s perfect for adding a touch of color to any fabric item. Fabric spray paint is an easy way to add color to fabric items. It’s also a great way to personalize items. BEST PAINT FOR HAND PAINT Looking for a way to add some color …

Fabric Spray Paint Does It Work: Yes, fabric spray paint does work. It can be used to change the color of fabric or to add patterns and designs. It is important to test the spray paint on a small area of the fabric before using it on the entire piece, to make sure that you are happy with the …

How Does Fabric Spray Paint Work: There are a few different types of fabric spray paint, but they all generally work in the same way. The paint is contained in a can with a nozzle attached to the can. When you press down on the nozzle, the paint is released in a fine mist and coats the fabric evenly. BEST …

Does Fabric Paint Work on Metal: Yes, fabric paint can work on metal. It is best to use a primer before painting so that the paint will adhere better and last longer. You can also use spray paint for a more even coverage. BEST PAINT FOR HAND PAINT If you’re looking for a quick and easy way to add some color …

Does Fabric Paint Work on Lycra: Yes, fabric paint does work on Lycra. In fact, it can be a great way to add some color and personality to your workout gear. Just be sure to use a paint that is specifically designed for use on fabric, and follow the instructions on the label carefully. BEST PAINT FOR HAND PAINT If you’re …

Does Fabric Paint Work on Jeans: Yes, fabric paint does work on jeans. You can use fabric paint to add a design or embellishments to your jeans. When working with fabric paint on jeans, it is important to test the paint on a small area of the fabric first to make sure that it will adhere properly and not bleed through. …

Does Fabric Paint Work on Faux Leather: Yes, fabric paint does work on faux leather. You may need to use a primer first, and then you can apply the paint as you would to any other surface. Fabric paint is a great way to add color and pattern to faux leather items, and it can also help protect the surface from wear …

Does Fabric Paint Work on Canvas: Yes, fabric paint does work on canvas. You can use it to add color and pattern to your canvas project. Just be sure to test the paint on a small area of the canvas first to make sure it adheres well and doesn’t bleed through. BEST PAINT FOR HAND PAINT If you’re looking for a …

Does Fabric Paint Work on Black: Yes, fabric paint will work on black fabric. You may need to use more coats of paint to get good coverage, but it is possible to get bright and vibrant colors on black fabric. BEST PAINT FOR HAND PAINT If you’re looking for a bold, vibrant look, then painting on black fabric is a great …

Does Fabric Paint Work on Denim: Yes, fabric paint does work on denim. You can use it to add embellishments or designs to your jeans. The key is to choose the right type of paint and to prepare the fabric properly before painting. BEST PAINT FOR HAND PAINT If you’re looking to add a little extra something to your denim clothing, …

Duplicolor Vinyl And Fabric Paint Adhesion Promoter: Duplicolor Vinyl and Fabric Paint Adhesion Promoter is a clear primer that helps paint adhere to vinyl and fabric surfaces. It can be used on both indoor and outdoor surfaces and provides a durable, long-lasting finish. BEST PAINT FOR HAND PAINT If you’re looking for a way to improve the adhesion of Duplicolor vinyl and …

Does Fabric Paint Work on Vinyl: Yes, fabric paint does work on vinyl. You will need to use a primer first and then you can use any type of fabric paint. BEST PAINT FOR HAND PAINT If you’re looking for a quick and easy way to add some color to your vinyl projects, fabric paint is a great option! You can …

Does Fabric Paint Work on Velvet: Yes, fabric paint does work on velvet. You will need to use a very soft brush and light pressure when applying the paint to the velvet. It is also important to make sure that the paint is completely dry before applying any additional layers. BEST PAINT FOR HAND PAINT If you’re looking to add a …