“What is wicking fabric or what does moisture-wicking mean?” is a common question among textile learners. Wiking finish is the special finishing procedure in textiles. The fabric is treated with a wicking agent called wicking fabric.

Furthermore, moisture-wicking fabrics have become increasingly popular in the sports and athletic industry due to their ability to keep athletes dry and comfortable during intense physical activity. These fabrics are specially designed to draw sweat away from the skin and move it to the surface of the material, where it can evaporate more easily. One of the key terms associated with moisture-wicking fabrics is “wicking,” which refers to the process of moving moisture away from the skin. In this context, wicking refers to the ability of a fabric to transfer moisture from one area to another, usually from the skin to the outer layer of the fabric. In this article, we will explore the mechanism of wicking and delve into the details of moisture-wicking fabrics to understand how they work and why they are so effective.

Wicking fabric:

Wicking fabrics are the special ultramodern technical fabrics that draw moisture away from the body. This fabric is highly technical polyester which unlike cotton and absorbs a very little amount of water.

Normally cotton absorbs 7% of the water of its weight. On the other hand, polyester absorbs only 0.4% of its weight. So that cotton absorbs water and makes itself heavy. But wicking polyester has a special cross-section and large surface area. They Pick up moisture and are carried away from the fabric.

So that wicking fabric makes the body cool and dry. The wicking fabric has two main properties:

- It Picks the water from the inside to the outer side of the body.

- Quick-dry the surface of the fiber molecule.

Where use wicking fabric: Wicking fabrics are used for the special purposes of use stated below

- For sportswear

- Sportswear use

- Activewear or clothing.

Types of Wiking Fabrics

Wicking fabric keeps the wearer dry and comfortable during physical activity or in hot and humid environments. There are several types of wicking fabrics available on the market, including polyester, nylon, merino wool, and bamboo. Each type of fabric has its unique features and benefits, such as breathability, quick drying, and antimicrobial properties. Polyester is the most common type of wicking fabric, and it is lightweight, durable, and resistant to wrinkles and shrinkage. Nylon-wicking fabric is also popular due to its strength and abrasion resistance. Merino wool and bamboo wicking fabrics are natural options that provide softness, insulation, and odor control.

Mechanism of Wicking Fabrics:

The mechanism of wicking fabric depends on three major factors:

- Yearn cross-section.

- Fabric construction.

- Wiking finish.

Yearn cross-section:

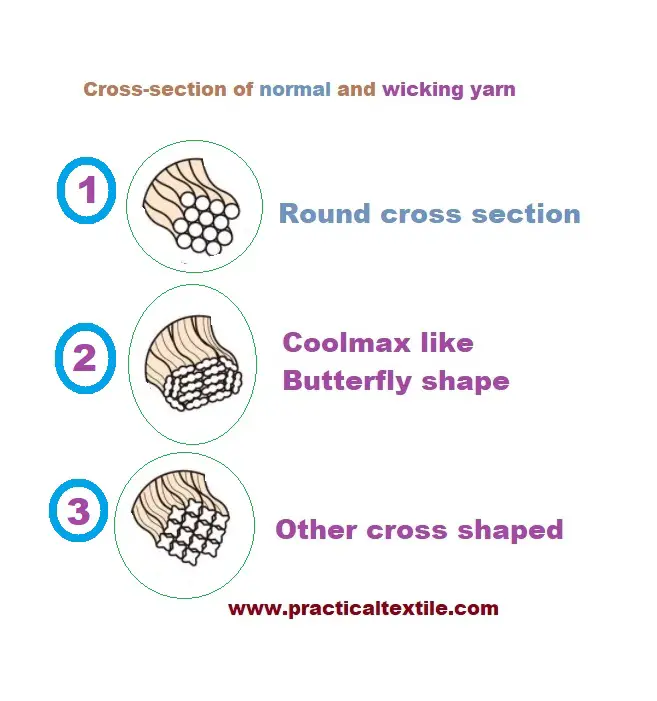

The main considering factor wicking fabric mechanism is the yarn cross-section. The normal yarn cross-section is a regular round shape. The wicking yarn cross-section is like a cross or flower in shape. So that there is a space to move water.

Here the water passes through the fiber cross-section with capillary properties. In this fabric, air can also pass through the fiber cross-section. This is why it is also called breather fabric.

- In the first number, the yarn cross-section is round in shape. Here we see that the space between the two rounds is so small. As a result, the water passing space is lower.

- On the 2nd number, the cool max yarn cross-section is butterfly shape and the water passing space is higher. So that here wicking properties is higher.

- On the last 3rd of the yarn cross-section is the cross shaft. here water passing space is higher. So that it contains wicking properties.

Fabric construction:

Fabric constriction is the second considered factor for wicking fabric. Our knit fabric structure has celebrity property. As a result, the sweat comes into contact with the fabric for diffusion into the outer large surface and evaporates quickly.

Wicking finish

Wicking finish is the special finishing that makes the usual polyester fabric into the wicking fabric. Here the wicking agent adds to the fabric and increases the wicking properties. Wicking agents increase the hydrophilic property.

This wicking agent can apply to the fabric in the exhaust as well as a continuous finishing procedure.

Application of wicking agent in exhaust method: step by step we are discussing the application below

Fabric load

Scouring and bleaching

Enzyme

Dyeing

Soaping

Wash and clear the water

Dosing Wicking agent at 30’C temperature

Run for 15 min

Unload.

Applicating the wicking agent in continuous finishing:

Unload after dyeing

Slitting

Stenter 1st bath: wicking agent 50g/l( Depends on the concentration of wicking agent)

Stenter 2nd bath: Cationic softener: 40g/l (depends on the concentration of the agent)

Compacting

Delivery to cutting

Conclusion

In conclusion, understanding the mechanism of wicking in moisture-wicking fabrics can greatly enhance our appreciation for innovative textile technology. Moisture-wicking fabrics offer several benefits, such as keeping us dry, comfortable, and odor-free during physical activity making them the best fit for athletes. By effectively wicking moisture away from the skin, these fabrics also help prevent skin irritation and chafing. It is fascinating to see how the unique construction and properties of these fabrics work together to provide such outstanding performance. With ongoing research and development in textile technology, we can expect to see even more advanced moisture-wicking fabrics in the future, further improving our comfort and performance during physical activity.

Research Links:

You May Read Some Other Articles below:

- Does Fabric Paint Go On Polyester

- What Is Cotton Linen Blend Fabric? It’s Knitting, Dyeing,& Finishing Development

- What Is The Cationic Polyester?

- Types Of Textile Testing | Textile Chemical & Physical Most Used Testing Methods

You can find us on: