The cotton nylon blend fabric dyeing process is a unique dyeing procedure. The knit fabric dyeing industry uses an uncommon dyeing process. Cotton dyeing is an alkaline medium process. Nylon dyeing is an acidic medium dyeing process. On the other hand, cotton needs reactive dyes, and nylon needs acid dyes. As a result, it is a critical dyeing process.

So it needs two-bath dyeing processes to give it a solid look. First, we have to dye the cotton part, and then we have to dye the nylon part. We can also reverse it. Cotton dyeing is a good first step. Because reactive dyes have better fastness properties than acid dyes.

In the cotton-nylon blend fabric dyeing process, cotton parts need 60 °C for dye fixup, and nylon parts need 98 °C–100 °C, temperature for bonding. As a result, the reactive dye can be slightly lighter at 98 °C. For this reason, we should keep the cotton shade 10% darker than the master shade.

50% Cotton 50% Nylon blend knit fabric dyeing process

Step-by-step dyeing processes are given below

The cotton part dyeing process follows

⇓

Ctn part dyeing 10%-15% dark BD

⇓

Nylon part dyeing

⇓

PH 5.0-5.50

⇓

Dyes 3% (according to required shade%)

⇓

Rise Temperature to 40⁰C

⇓

Color dosing=10 minute

⇓

Rise temperature 98⁰C (Grade=1⁰C/minute)

⇓

Runtime=30 minute

⇓

Colling at 75⁰C

⇓

Shade check

If the shade is ok then drain

⇓

Wash clear

⇓

Soaping agent inject

⇓

Rise temperature at 80⁰C

⇓

Runtime 15 minute

⇓

Shade check

⇓

Fixing with a fixing agent at a normal temperature 300c

⇓

Check the pH of 5-5.50

⇓

Softener both for cotton and nylon

⇓

Unload

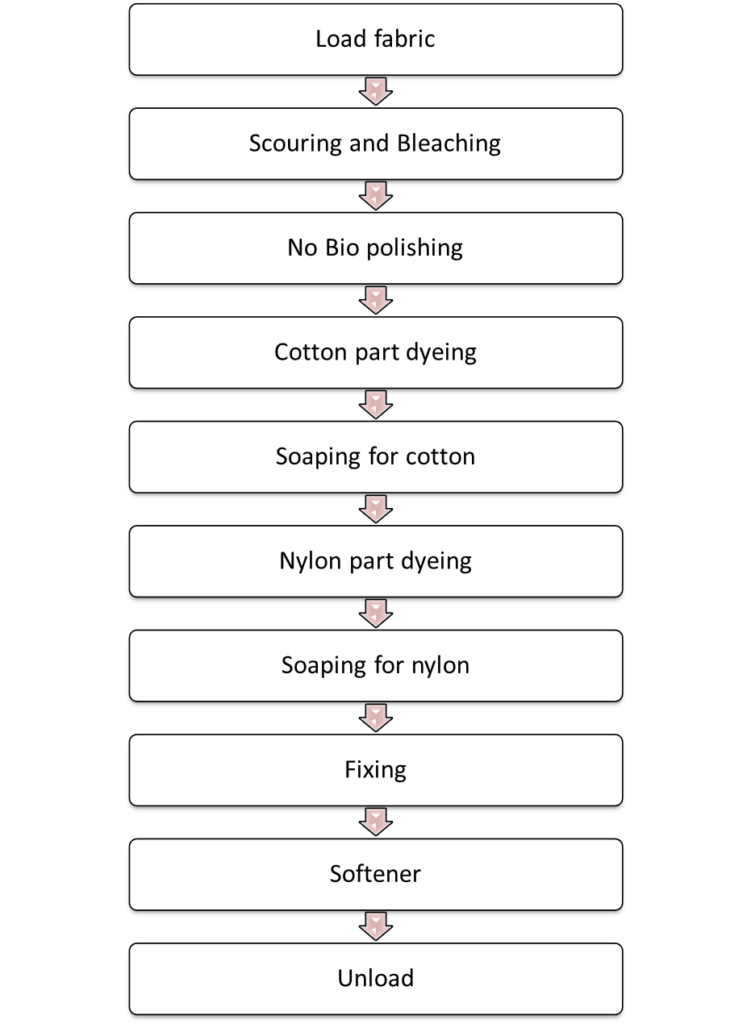

Cotton nylon blend fabric dyeing process flow chart:

The cotton-nylon blend fabric dyeing process starts with a step called “pre-treatment,” in which scouring and bleaching agents are used to get rid of dirt and make the surface clean. The fabric is then dyed with reactive dyes, which react chemically with the fibers to make bonds that are strong and last a long time.

After the fabric is dyed, it goes through a series of washing and finishing steps to make the colors last longer and make the fabric look better overall. A typical flow chart for this process shows the stages of loading the fabric, pre-treatment, dying, washing, and finishing. To get consistent and high-quality results, the process needs to be carefully controlled for temperature, pH, and the amount of dye used.

Why cotton nylon blend dyed fabric is so popular in the present world:

Cotton-nylon fabric is a popular textile choice for a variety of reasons. Here are some reasons why the cotton-nylon blend fabric is so popular:

- Durability: Cotton-nylon blend fabrics are known for their durability and strength. The combination of cotton and nylon fibers creates a fabric that can withstand wear and tear, making it ideal for clothing and outdoor gear.

- Comfort: Cotton is a natural fiber that is soft and breathable, while nylon is a synthetic fiber that is lightweight and moisture-wicking. When blended together, these fibers create a fabric that is comfortable to wear and can regulate body temperature.

- Versatility: Cotton-nylon blend fabrics can be used for a variety of applications, from clothing to upholstery. The fabric can be dyed in a range of colors and patterns, making it a versatile choice for different styles and designs.

- Easy care: Cotton-nylon blend fabrics are easy to care for and can be machine-washed and tumble-dried. They are also resistant to wrinkles, making them a popular choice for travel clothing.

- Cost-effective: Cotton-nylon blend fabrics are often more cost-effective than pure cotton or pure nylon fabrics, making them an attractive option for manufacturers and consumers.

In summary, cotton-nylon blend fabrics are popular because they are durable, comfortable, versatile, easy to care for, and cost-effective. The combination of cotton and nylon fibers creates a fabric that is ideal for a variety of applications and can meet the needs of different industries and consumers.

Conclusion:

The given Cotton nylon blend fabric dyeing process is the most famous process in the textile industry for knit fabric. Everyone can use it for production. Tips and tricks are given below:

- The cotton part must have been dyed first.

- PH must be controlled properly.

- The depths of the cotton color and the depth of the nylon color should be the same. On the other hand, a melange effect will happen.

Research link:

You may read some other articles:

FOR MORE INFO VISIT KNIT DYEING DETAILS

You can find us on: