Dyeing fabric is a difficult and delicate process that requires skill and attention to detail. Viscose fabric is particularly challenging to dye due to its unique properties. In this article, we will discuss the intricacies of the viscose fabric dyeing process and explain why it is difficult but rewarding. We will also give key tips on how to successfully achieve vibrant colors with this type of fabric.

The viscose fabric dyeing process is a sensitive one in the dyeing industry. Viscose is regenerated cellulosic fiber. Its strength is not as good as cotton fiber. As a result, it needs extra care during processing. It is famous for its end uses. The soft hand feels and glossy effect makes it famous. viscose dyeing with reactive dyes because it is a cellulosic fiber. Let’s discuss the process.

The knitted viscose fabric dyeing process is discussed below:

Viscose dyeing process step by step:

Anticreaseing agent + Oil remover inject= Inject

⇓

Raise Temp to 70⁰C

⇓

Load fabric

⇓

Runtime 5min

⇓

Soda ash light dissing 7min

⇓

Runtime 10min

⇓

Drain

⇓

Scouring chemical inject = Detergent+anticreaseing agent+ secquestering agent

⇓

Soda ash light dossing 7min

⇓

Raise the temperature to 70⁰C

⇓

Hydrogen Peroxide inject

⇓

Raise the temperature at 80⁰C

⇓

Runtime 15min

⇓

Cooling at 75⁰C

⇓

Shade check (Brightness)

⇓

Drain

⇓

Raise temperature To 70⁰C

⇓

Runtime 10 minute

⇓

Wash to clear water

⇓

Drain fill

⇩

Inject acetic acid to neutralize the fabric

⇩

Inject Peroxide killer

⇩

Runtime 10 minute

⇓

Check with peroxide paper

⇓

If ok then drain and wash

⇓

Drain fill

⇓

Leveling Ph check 6.20

⇓

Leveling Dosing at 60⁰C= 3 Minutes

⇓

Color Dosing 25 Minute

⇓

Runtime 10 minute

⇓

1 st 10% Salt Dosing 15 Minute

⇓

Runtime 10 Minute

⇓

2nd 20% Salt dosing 15 Minute

⇓

Runtime 10 Minute

⇓

3rd 70% Salt Dosnig 15 Minute

⇓

Runtime 10 Minute

⇓

Salt Sample check (Levelness, availability of all colors)

⇓

If everything ok

⇓

1st 10% Soda dosing 15 minute

⇓

Runtime 10 minute

⇓

90% Soda dosing 25 minute

⇓

Runtime 10 minute

⇓

Sample check for shade

⇓

If the required shade is ok then

⇓

Drain & Wash for 10 minutes

⇓

Raise temperature at 80⁰C,

⇓

Run for 10min

⇓

Drain fill and Wash

⇓

Soaping chemicals injected into the machine

⇓

Temperature up to 90⁰C (According to shade)

⇓

Runtime 10min

⇓

Drain and wash until clear water

⇓

Dossing the fixing agent for 5 minute

⇓

Runtime 15 minute

⇓

Drain fill wash

⇓

Adjust ph 5

⇓

Cationic Softener Dossing for 5 minutes

⇓

Runtime 10 minutes

⇓

Sample check for softness and final shade

⇓

If ok then unload

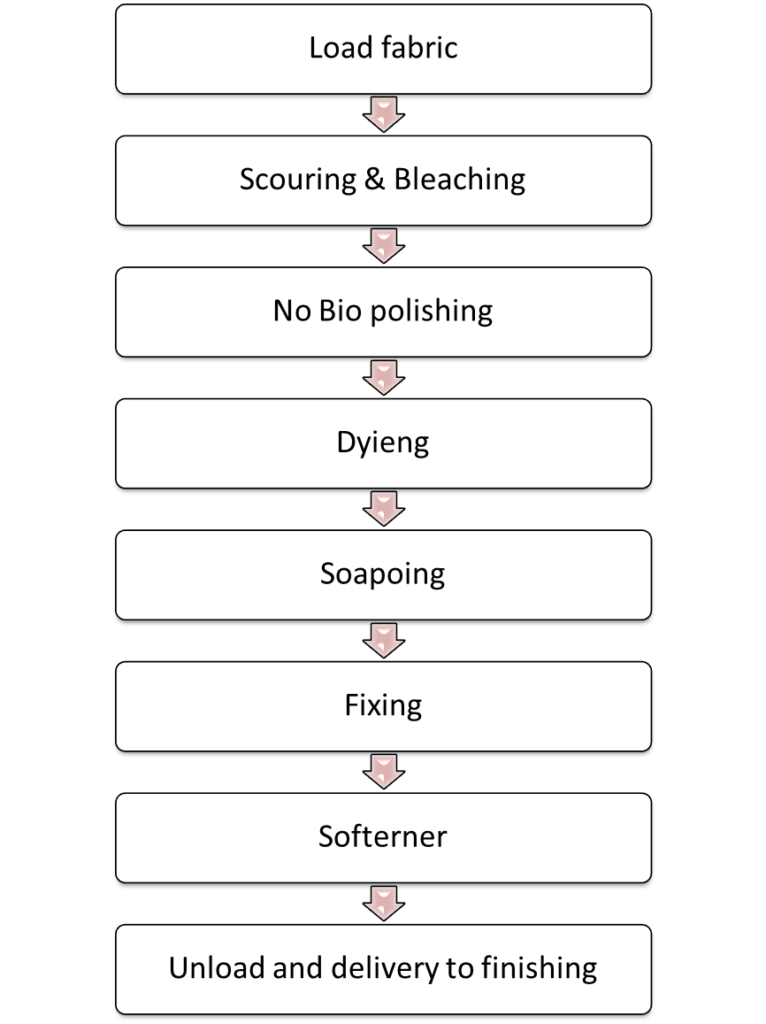

Viscose Knit fabric dyeing process flow chart:

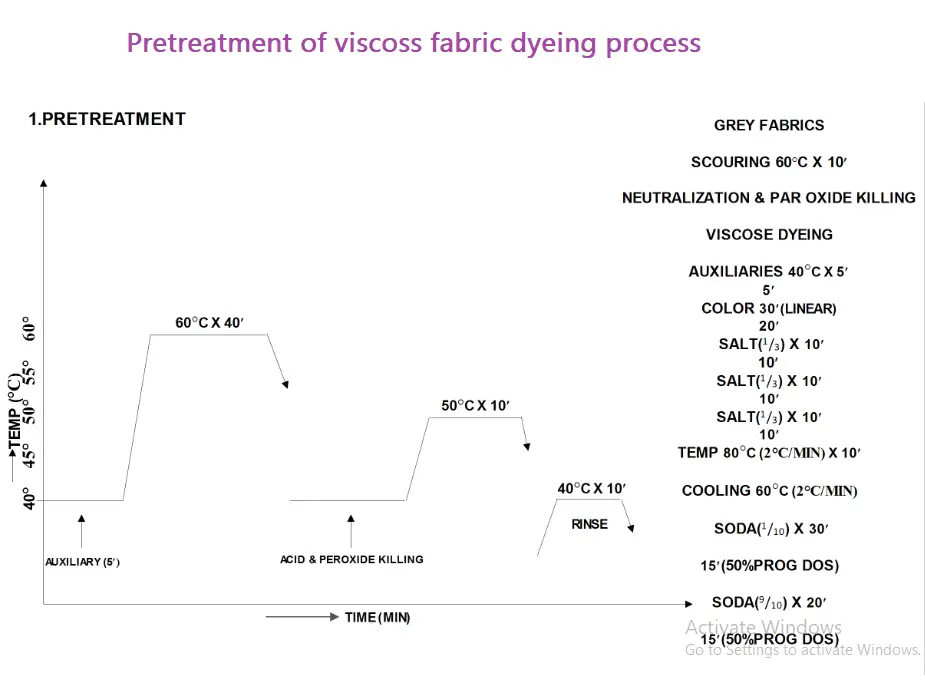

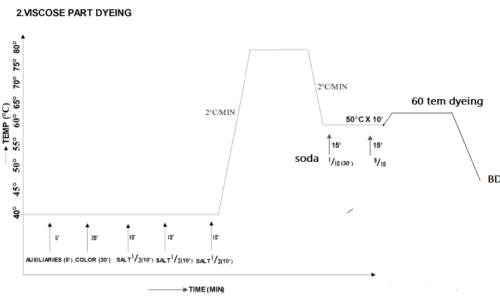

Viscose fabric dyeing process by Diagram or a time vs temperature Graph:

A time vs temperature graph of viscose fabric dyeing process by an image:

Viscose Dyeing Process Tips And Tricks:

- Batch preparation must have to be proper. ( Need full back sewing ).

- Must have followed the accurate process.

- Cycle time must be within 2 minutes to 2 min 30sec.

- The salt ph on the dye bath must be below 7.

- Should not be used caustic soda.

- The cationic softener should not use for navy or black colors because it can create a white spot on the fabric. If need extra softness we can use a softener on stenter machine.

Viscose fabric dyeing VS cotton fabric dyeing:

Viscose and cotton are two different types of fabrics with distinct dyeing characteristics. Here are the differences between the two:

- Absorbency: Cotton has high absorbency, which means it takes up dyes quickly and easily. In contrast, viscose has low absorbency and requires special pre-treatment to achieve good dye uptake.

- Dye types: Cotton can be dyed using a wide range of dye types, including natural, direct, reactive, and vat dyes. Viscose, on the other hand, is best dyed using acid dyes because it is sensitive to high temperatures and alkaline conditions.

- Colorfastness: Cotton has good colorfastness to washing and light, while viscose is more prone to fading and discoloration when exposed to water and light.

- Durability: Cotton is a more durable fabric than viscose, which means that the colors will last longer and the fabric will hold up better over time.

- Environmental impact: Viscose is made from wood pulp, which makes it a less sustainable option than cotton, which is a natural fiber. However, cotton cultivation requires significant amounts of water and pesticides, which can have a negative impact on the environment.

In summary, cotton is easier to dye and produces more vibrant and long-lasting colors than viscose. Viscose requires special pre-treatment and dyeing conditions to achieve good dye uptake and colorfastness. However, cotton is less environmentally friendly than viscose due to the water and pesticide requirements of cotton cultivation.

Conclusion:

In conclusion, the viscose fabric dyeing process is a lengthy and precise procedure that requires an experienced and skilled dyer to ensure the fabric is dyed correctly. The steps of the process involve scouring, bleaching, neutralizing, mercerizing, and dyeing, each of which must be completed carefully to ensure colors remain vibrant and true. By following all of these steps properly, the end product will have a beautiful color and texture.

In addition to the steps mentioned above, the viscose fabric dyeing process also involves temperature, pH, time, and pressure, all of which must be carefully controlled to get the color and shade you want. Also, to make the textile industry less harmful to the environment, it has become more important in recent years to use eco-friendly and sustainable dyeing methods. Even though there are problems, dyeing viscose fabric is still an important step in making high-quality textiles that are used in many industries, such as fashion, home textiles, and cars.

Research link:

You may read some other articles

FOR MORE INFO VISIT KNIT DYEING DETAILS

[…] viscose fabric dyeing process- for practical use 2021 […]

[…] viscose fabric dyeing process- for practical use 2021 […]

[…] viscose fabric dyeing process- for practical use 2021 […]

[…] viscose fabric dyeing process- for practical use 2021 […]

[…] viscose fabric dyeing process- for practical use 2021 […]

[…] viscose fabric dyeing process- for practical use 2021 […]

[…] viscose fabric dyeing process- for practical use 2021 […]

[…] viscose fabric dyeing process- for practical use 2021 […]