Double pique knit fabric is a special type of fabric. Its Dyeing and finishing process is also special in the present world. The dyeing finishing process and its flow chart are unique from other fabrics. Recently I developed a 100% cotton pique knit fabric and I am sharing here my experience with all the process parameters. Here also stated the testing process and actual data of my development according to different ISO testing methods.

Double Pique knit fabrics are made of thick single yarns that create a diamond pattern when knitted. The double pique pattern is created by knitting two stitches together and then knitting another stitch in the next hole. This creates a tighter knit than regular pique and creates a more dense and strong fabric with texture to it. Double pique fabrics generally have a thick woven appearance and can be used for many home projects such as kitchen aprons, tablecloths, and placemats.

Target Parameter Double Pique Fabric

| Buyer | Celio |

| fabric Type | 100 % Cotton |

| Composition | 100 % cotton |

| Color Name | As swatch |

| Shade% | 5.38 |

| Required Dia | |

| Required GSM | 250 |

| Special Note |

Yarn Information

| Yarn count and Type | 22/1 cotton |

| Yarn composition | 100 % cotton |

| Yarn lot | 307/ 21 |

| Yarn Brand | Blank |

Knitting Parameter

| Machine Dia and Gauge | 25*24 G |

| Total needle | 1884 |

| Stitch length | 29 |

| Machine No | 40 |

| Machine Brand | Fukuyama |

| Machine RPM | 10 |

| Grey Width | 176 Cm (open) |

| Grey GSM | |

| Gray Wash | |

| Gray Wash GSM |

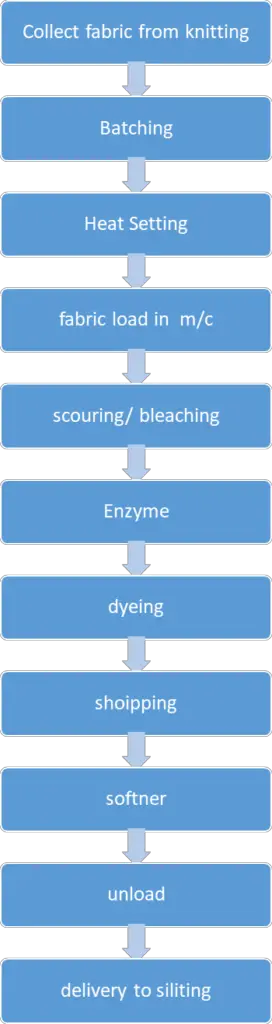

Dyeing Flow Chart:

Dyeing recipe :

| Buying House : | Practical Textile |

| Buyer : | Practical Textile |

| Order No : | 01 |

| Machine No : | |

| Type of fabric : | s/j CTN |

| Sro No : |

| Date : | 1.01.22 |

| Batch No : | 0000 |

| Shade/Color : | Any |

| Quantity : | 50 Kg |

| L.:R. : | |

| Total Water : | 400 Lt |

| REQUISITION FO DYESTUFF & CHEMICALS |

| SL# | Name of the chemicals | G/Liter | % | Req’d Qty. In Kg | Issues Qty. | Remarks |

| Pretreatment : | ||||||

| 1 | ||||||

| 2 | Detergent | 0.80 | 0.240 | |||

| 3 | Anticrese | 2.00 | 0.600 | |||

| 4 | Caustic | 2.00 | 0.600 | |||

| 5 | H2O2 | 2.50 | 0.750 | |||

| 6 | ||||||

| 7 | ||||||

| Peroxide killer | 0.15 | 0.045 | ||||

| 8 | Acitic Acid | 1.00 | 0.300 | |||

| 9 | ||||||

| 10 | ||||||

| 11 | ||||||

| 12 | ||||||

| Dyeing : | ||||||

| 13 | Leveling agent | 1.00 | 0.300 | |||

| 14 | Anticreseing agent | 2.00 | 0.600 | |||

| 15 | ||||||

| 16 | Color: red | 1.026% | 0.513 gm | |||

| 17 | Color : red | 1.188 % | 0.59 gm 400 mg | |||

| 18 | Color: Blue | 2.2 % | 1 kg 100 gm | |||

| 19 | ||||||

| 20 | Gluber Salt | 70.00 | 28,000 kg | |||

| 21 | Soda Ash Lt | 15.00 | 6,000 kg | |||

| After Treatment : | ||||||

| 22 | Soaping agent | 0.80 | 0.240 | |||

| 23 | anticreseing agent | 0.50 | 0.150 | |||

| 24 | ||||||

| 25 | Fixer | 1.00 | 0.300 | |||

| 26 | ||||||

| 27 | Softener | 2.00 | 0.600 |

Dyeing process:

Loading

Detergent+ anticreaseing agent injects

Temperature rise 50 degree

Caustic dossing 5 min

rise the temperature to 70 degrees

Hydrogen Peroxide inject

Rise the temperature to 98 degree

run for 60min

cooling and drying

normal hot

peroxide killer injects

acid for neutralization

enzyme

wash then leveling

Temperature 60c

Leveling dosing 3 minute

Runtime 10 minute

Color dosing 25 minutes (Linear)

Runtime 10 minute

1st Salt dosing 10 minute

Runtime 10 minute

2nd salt dosing 10 minute

Runtime 10 minute

Sample check

1st Soda dosing (1g/l) 25 minute

Runtime 10 minute

2nd soda dosing 10 minute

Runtime 10 minute

Sample check

If shade ok then

soaping

softener

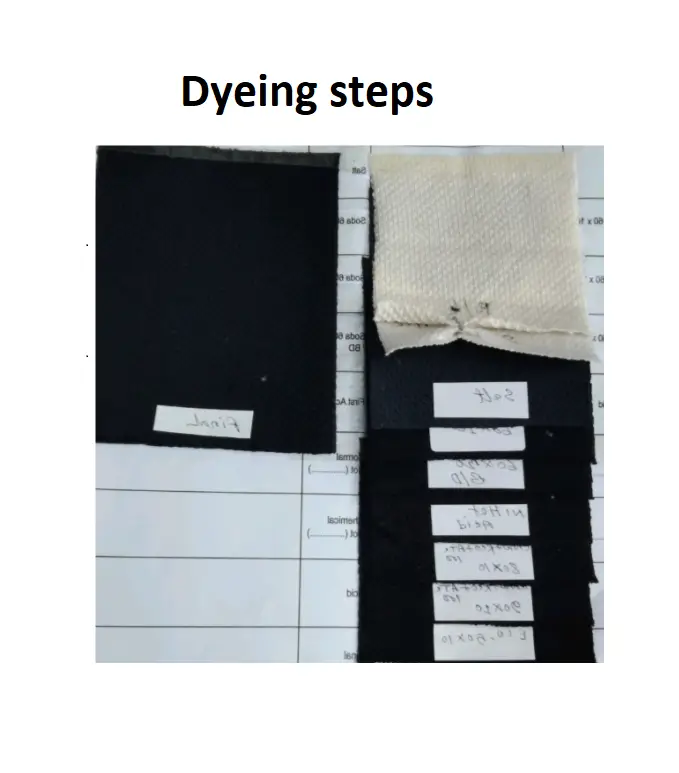

Actual Dyeing procedure Steps image which I did practically

Double Pique knit fabric finishing flow chart:

Slitting Parameter:

| Machine Speed | 40 |

| Padder pressure | 1.5 kg |

| Over Feed | Blank |

| Fabric In Diameter | 25 |

| Fabric Out Diameter | 170 |

Stanter/Dryer

| Name | Heat Set | Dry Time |

| Width set | 170 | |

| Over Feed | 59 % | |

| Temperature | 120 | |

| RPM/ Speed | 13 | |

| Pedder Pressure | 312 | |

| Vibration | biank | |

| Softener Type | Cationic | |

| After Dry Width | 170 -165 | B dia= 170-163 |

| After Dry GSM | 250-210 | B. gsm=250-220 |

Stenter/Compacting

| Stanter /Dryer | Compacting | ||

| Width set | 140 | ||

| Over Feed | 59% | Temperature | 120 |

| Temperature | 120 | Steam Pressure | 30 |

| RPM/ Speed | 13 | Width set | 170 |

| Padder Pressure | 312 | Over feed% | 35% |

| Vibration | blank | RPM/Speed | 12 |

| Softener Type | Cationic | Compaction% | blank |

| After Dry Width | 170-165 | After Width | 170 -163 |

| After Dry GSM | 250-210 | After GSM | 250-220 |

| Wash gsm | 250 |

Shrinkage:

Length=

Width=

SP%=

Test Report:

Final width= 130 f145 Final GSM=270 f 265

Shrinkage with tumble dry:

Length= -5%

Width=-5 %

SP%=2%

Shrinkage of line dry:

Length=-1.2%

Width=+2.8%

SP%=2%

Testing of Double pique knit fabric with ISO method:

The conclusion of the test methods

| Sl. No. | Test Name | Results (A) |

| 01 | Dimensional Stability to washing | Pass |

| 02 | Angular Variation After Washing | Pass |

| 03 | Pilling Resistance (ICI BOX Method) | Pass |

| 04 | Mass per unit area | Pass |

01. Dimensional Stability To Washing

Test Method: NF EN ISO 5077/6330/3759

Wash Condition: Normal Program, Machine wash @40ºC, Line dry, Used Front loading washing Machine Wascator with 15.4gm ECE reference Detergent, 4gm Sodium Per borate, and 0.65gm TAED Solution With 2.0 Kg Load.

| Sample (A) | After Three Wash | |

| Direction | Result | Client Requirement |

| Length | -1.2% | ±5% |

| Width | +2.8% |

Remark: (+) Means Extension And (-) Means Shrinkage

02. Angular Variation After Washing

Test Method: ISO16322-1: 2005

Wash Condition: Normal Program, Machine wash @40ºC, Line dry, Used Front loading washing Machine Wascator with 15.4gm ECE reference Detergent, 4gm Sodium Per borate, and 0.65gm TAED Solution With 2.0 Kg Load.

| Sample (A) | Result (After Three Wash) | Client Requirement |

| Spirality | 0.0% | 5% |

03. Resistance Of Pilling (ICI BOX Method)

Test Method: NF EN ISO 12945-1:2020

Wash Condition: After Three Wash (ISO 6330, Normal Program@40ºC, Line dry)

| Sample (A) | Result | Client Requirement |

| After 14, 400 Cycle, 4hrs | ||

| Grade | 4 | 4 |

| Note: Fuzzy Effects were observed |

04. Mass Per Unit Area

Test Method: NF EN ISO 3801: 1977, method 5

Test Stage: As Received Stage

| Sample (A) | Result | Client Requirement |

| Average | 273.5 g/m2 | 280 g/m2 (±5%) |

Conclusion:

I discussed the 100% Cotton Double Pique Knit Fabric Dyeing And Finishing Development which I did recently. All the parameters and processes are actual. Anyone can apply the parameter. Any confusion comments me. I will give the solution.

Research Links:

- Piqué (weaving) – Wikipedia

- Cotton | Description, History, Production, Uses, Botanical Name, & Facts | Britannica

You may read some other articles also:

- 5 Best Clothing Fabric Dye Color For Clothes Reviews 2022

- 3 Best Multi-Needle Embroidery Machine For Home Business 2022

- The Technical Selection Of Best Powder Dye For Tie Dye 2022

- 5 Best Dyes For Clothes To Buy in 2022

- What Is Cotton Interlock knit fabric? It’s Knitting Dyeing and Finishing Development.

You can find us on:

[…] 100% Cotton Double Pique Knit Fabric Dyeing And Finishing Development 2022 […]

[…] 100% Cotton Double Pique Knit Fabric Dyeing And Finishing Development 2022 […]