Yes, our topic is “What Is Scuba Double Knit Fabric Details & Use For?”. We will discuss its uses, knitting, dyeing, finishing, testing, sewing, and money other things. Technically, Scuba double knit fabric is nothing but the technical combination of two knit fabrics by polyester. Two knit fabrics may be cotton, viscose, or any other blend. Every combination has its own end uses and properties and characteristics.

Scuba-like as neoprene fabric and they are different according to their production process and material and characteristics. Scuba is very smooth and springy. It’s not perfect for making wetsuits for scuba divers.

It is a double-knit fabric. Do you want to know what scuba fabric is used for? It is used primarily for dresses like skirts, dancewear, etc. Scuba materials are used for a variety of fashions and styles. It’s one kind of smooth and synthetic double-knitted fabric.

It has already been said that scuba fabric is made with 100% polyester with mechanical stretches. Double-knit scuba fabric is normally 56-60 inches wide. You can easily sew this fabric. The material is lovely and excellent. It is finely woven. So it’s so durable and smooth. Its approximate weight is about 10.2oz per yard. And its thickness is approximately 0.75 mm.

Scuba double knit fabric is solid and perfect for any fashionable dress you need. Such as scuba fabric wedding dresses, scuba fabric tops, scuba fabric hoodies, scuba fabric jackets, scuba fabric for swimwear, etc.

Scuba knit fabric uses:

Scuba fabric is the most acceptable for all types of fashionable dresses. Because it is made with polyester, which makes it smooth and shiny. Also, the cloth of this fabric is durable, strong, and has mechanical stretches. If you notice, stylish clothes are made of very smooth material. The scuba fabric is very soft, nicely woven, and beautiful. This fabric is also double-knitted and easy to sew. Scuba Fabric Wedding Dress is also very popular. It is also used in waterproof dresses—for example, scuba-fabric swimwear. Tops, hoodies, jackets, etc, are also made in the scuba fabric pattern.

History of scuba fabric:

In the 1930s developed a type of chloroprene rubber was. DuPont made it. This type of chloroprene rubber e was mainly petroleum-based polychloroprene. Scuba fabric is made by following the neoprene fabric. These fabrics have a neoprene label attached to them. And these are petroleum-based polychloroprene.

Scuba fabric has been used since the 1930s. There was no natural rubber during World War II. Then the use of this artificial rubber scuba fabric increased a lot. This fabric is made of waterproof swimwear or a wetsuit. Thus the use of scuba fabrics gradually increased.

Advantages of Scuba Knit Fabric:

Have you any idea about the advantages of Scuba knit fabric? There are many advantages of Scuba knit fabric that are given below:

- Super smooth and comfortable to wear

- It is water resistant and so swimwear is also made from it

- It is a highly stretchable fabric

- You can get extra support from the scuba fabric

- It is easy to sew and nicely woven

- Fantastic to wear the dresses made by it

- The ability to retain heat exists

- Perfect for wetsuit and fashionable & stylish wear

- This fabric is made with 100% polyester with mechanical stretches

- It is more durable, long-lasting, and strong

Disadvantages of Scuba knit Material:

This synthetic artificial rubber was used during World War II as there was no natural rubber. From then on, its use started in circulation. The advantages of this fabric are comparatively much more. Some disadvantages are given below:

- The Scuba knit fabric material is not biodegradable

- You can’t use too much heat. This fabric will melt if you use too much heat

- When the wear of this fabric is stretched, the pattern is disrupted.

- This fabric is not breathable.

- No fabric is 100% perfect. There are also some disadvantages to such scuba fabrics. However, it is relatively tiny.

How many kinds of Scuba Fabric are there?

There are two types of scuba fabric. Such as:

1. Petroleum-based polychloroprene:

Petroleum-based polychloroprene is made with butadiene. Butadiene is derived from fossil fuels. This petroleum-based polychloroprene is a type of chloroprene rubber. DuPont made this chloroprene rubber in the 1930s. This is the basic form. But it is not durable. You can see the label on the top of the scuba fabric to be sure. If Neoprene is labeled, it will be petroleum-based polychloroprene.

2. Limestone-based polychloroprene:

Limestone-based polychloroprene is more durable than petroleum-based polychloroprene. Because it is made with one kind of chemical which is manufactured from a polymer.

Knitting, dyeing, finishing, and testing of scuba double knit fabric with a complete practical experiment

we will discuss the stated steps of scuba double knit fabric. Here we will share a complete procedure that a developed. Let’s start

If Target parameter:

| Fabric type | Scuba fabric |

| Composition | 75% Recycle polyester+ 18% viscose+7% elastane |

| Color Name /Pantone | Black |

| Shade % | |

| Repaired Diameter | |

| Required GSM | |

| Special Note | The special fabric needs special care |

Imported yarn parameter will:

We imported yarn from a reputed company for this scuba fabric. I am sharing the below parameter.

| Yarn count and Type | 26 S/1 viscose Vortex+75D AC Polyester |

| Yarn Composition | 75% viscose+22%polyester+3%elas |

| Yarn Brand | A Reported Company |

Knitting setting Parameters scuba fabric will:

The setting parameter of knitting to get our target fabric is in the below table.

| Machine Dia and Gauge | 34 & 28G |

| Total Needle | 5978 |

| Stitch length | 42+28.5 |

| Machine Brand | |

| Machine RPM | 12 |

After completing knitting we get the fabric parameter stated below table.

| Grey fabric width (Dia) | 206 cm open |

| Gray GSM | 366 |

Dyeing of scuba fabric:

Normally scuba fabric will be a combination of cellulose and polyester blend. So that the

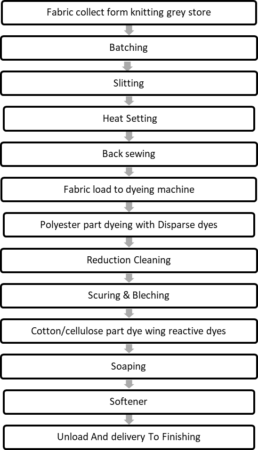

Dyeing flow chart of the scuba fabric:

Scuba fabric dyeing procedure:

Scuba is two part dyeing process. One is the polyester part the other is the cellulose part. so the process is discussed below:

Polyester Part Dyeing

Oxalic acid and increasing agent hot 80’c temperature

Run 10min

Drain and fill

Control Ph 4.5

Leveling of dispersed dyeing and Antecreaseing agents inject

Run 10min

Rise temperature 80’c

Color(disperse dyes) dossing 30min

Run 10min

Rise temperature 130’c Grade 0.5

Run 45min

Cooling at 80’c Grade 0.5

Check the shade

If ok drain the dye batch

Reduction Cleaning

Dossing the soda ash lt for 10min

then rise the temperature at 80’c

rise the chemical tank temperature 80’c also

inject the hydro’s

rise the temperature to 95’c

run 15min

cooling at 80’c

drain

Scouring & Bleaching

Detergent + Anti-creasing agent = Inject

Temp 40c*= Fabric Load

Soda ash light Dosing

Temperature 60c*20 Minute

Temperature 70c

Sequestering agent + H2O2 Dosing 5 Minute

Temp to 95’C & run 50 Minute

Cooling at 78’C

Sample check

If the sample ok then Drain

Normal Hot 70*10

Peroxide Killer 60*10 Minute

Drain

Naturalization with acid

Drain

Wash 10 min

Dyeing Viscose part

Levelling Ph check 6.20

Levelling Dosing 60c 3 Minute

Color Dosing 25 Minute

Runtime 10 minute

1st 10% Salt Dosing 15 Minute

Runtime 10 Minute

2nd 20% Salt dosing 15 Minute

Runtime 10 Minute

3rd 70% Salt Dosing 15 Minute

Runtime 10 Minute

Salt Sample check

1st 10% Soda dosing 15 minute

Runtime 10 minute

90% Soda dosing 25 minute

Runtime 10 minute

Sample check

BD

Hot wash

Acid

Unload

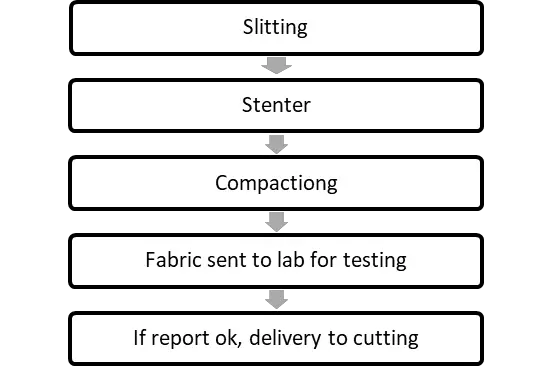

Finishing flow chart of scuba double knit fabric:

The finishing flow chart of the fabric is given below

Types of Testing required to test for scuba double knit fabric:

There are some types of testing is required to test the scuba fabric which is given below:

| Sl. No. | Test Name | Ratting requirement |

| 01 | Dimensional Stability to washing | ±5% |

| 02 | Spirality After Washing | 5% |

| 03 | Color Fastness to Washing | 4 out of 5 |

| 04 | Color Fastness To Rubbing | 4 out of 5 |

| 05 | Color Fastness To Water | 4 out of 5 |

| 06 | Color Fastness To Perspiration | 4 out of 5 |

| 07 | Mass Per Unit Area | As requirement |

| 08 | Fiber Analysis | Rating requirement |

The most effective test method and process are dissing below:

01. Dimensional Stability To Washing

Test Method: ISO 5077+ EN ISO 6330:2012

Test Condition: Normal Program, Machine wash 4N@40°C, Tumble Dry, 15.4gm ECE, 4gm Sodium Perborate & 0.65gm TAED reference Detergents, Wascator washing machine with 2.0 kg load.

02. Spirality After Washing

Test Method: ISO 16322-3:2005(en)

Test Condition: Normal Program, Machine wash 4N@40°C, Tumble Dry, 15.4gm ECE, 4gm Sodium Perborate & 0.65gm TAED reference Detergents, Wascator washing machine with 2.0 kg load.

03. Color Fastness To Washing

Test Method: EN ISO 105 CO6-A2S:2010

Test Condition: Temperature at 40 degrees, Time 30 min, Detergent 4g/l ECE,1 g/l Sodium Perborate With 10 Pcs Steel Balls

04. Color Fastness To Rubbing

Test Method: DIN EN ISO 105 X12:2016

05. Color Fastness To Water

Test Method: ISO 105 E01:2013

Test Condition: Temperature at 37±2ºC, Time 4 hours.

06. Color Fastness To Perspiration

Test Method: DIN EN ISO 105 E04:2013

Test Condition: Temperature at 37±2 degrees, Time 4 hours.

07. Mass Per Unit Area

Test Method: DIN EN 12127: 1997-12

08. Fiber Analysis

Test Method: ISO 1833:2006

End of test

Sewing Tips for Using Scuba:

Sewing tips for you for using scuba material:

- Firstly you have to pre-wash the Material that you want to sew. Because of washing, shrinkage may occur. So, before measuring and cutting the scuba fabric material, try to wash it.

- Try to avoid the use of an overlocker knife. In the case of scuba fabric, it is better to trim by hand. Cutting by hand is a great trick.

- Try to work slowly. It is easy to work to sew scuba material. But you can avoid it by doing work slowly. If you make an error in sewing, you have to unpick the stitches. It makes you waste your time and can leave marks on the stitch.

- Scuba fabric is smooth and 100% polyester. So it slips during sewing. You should use a ballpoint or stretch needle for this soft slipping fabric.

- The time of heating for washing or ironing, you have to be careful. Scuba fabric is too heating sensitive. So try to be cautious about it.

Printing of Scuba knit fabric:

Printing on scuba fabric is a trendy garment. The smooth print on this fabric looks fantastic. Printed scuba fabric tends to be quite heavy. Spoons are made using yarn. It is a little harder to publish in this smooth fabric. Because these fabrics are pretty slippery. Since scuba fabric is lovely for fashionable clothing, its printing is very famous. Printed scuba fabric is a stiff fabric made of poly blend fiber. Lighting through the scuba fabric will cause the pattern to slowly move away from the surface, making the fabric appear partially opaque.

What is neoprene fabric?

Do you want to be familiar with the fabric, Neoprene? Let’s explain all about it. In Mood’s fabric dictionary, it is said that Neoprene is a synthetic rubber often used in making wetsuits, so the alternative is Scuba knit. It has many qualities. For its durability and strength, it has become increasingly famous day by day. It is also stain-resistant fabric. For its water-resistance quality, it is used to make wetsuits. Besides, it is smooth and full-coverage polyester fabric. For this, fashionable dresses are made with them.

Scuba fabric vs. Neoprene (What is the difference between Neoprene vs. scuba?

The body that scuba gives to garments is one of the reasons designers love it. The end also provides the coloration with a matte excellent. The period scuba is regularly used interchangeably with the period neoprene. Neoprene is a similar feeling cloth, but with one primary difference: Neoprene refers to a thin piece of foam. This foam is then sandwiched among thin layers of knitting to create neoprene cloth. While the fabric behaves similarly, neoprene cloth may be much less secure to put on because thin pieces of foam can get very hot for the wearer.

Different products of scuba fabric:

- Scuba fabric tops:

Scuba material is regularly related to figure-hugging frame contour attire or full skirts. Still, its structure and form are perfect for making a pinnacle that hangs away from the frame. Some single knits have an uncongenial addiction to migrating closer to skin creases, which isn’t usually the most flattering appearance for plus-length stitching. Double knit holds its form better.

However, the extra weight way that is now not handiest is it first-rate for no longer creasing, but it also does not tour towards the exact regions I’mI’m seeking to cover! I selected to make the sleeves out of an ordinary jersey an old T-blouse, in fact as it makes the pinnacle light and flowing on the hands and now not as toasty as though it became all crafted from scuba material.

- Scuba fabric hoodie:

Working in style, you notice plenty of clothes. Sometimes this will harden you to their impact. You turn out to be a piece blasé. But each so often, a bit of clothing will come along and, like all right clothes, must give you a portion of a rush. So what makes scuba material hoodies so high-quality? Firstly, it is warm but now not too hot. You can put it on rather than a jacket with a shirt on milder days. Secondly, it’s an easy conventional form.

Thirdly, the boozy hue works brilliantly with jeans or simple darkish trousers. Accordingly, it’s miles versatile. Aside from the hood, it also boasts a massive pocket at the front, suitable for stashing the odd bits and portions that don’t constantly feel healthy in bags. On a less practical note, and more alongside the lines of the clothes that give you a rush, this pinnacle has a happy sponge-like floor. This offers it a moderate sci-fi aspect.

- Scuba fabric for swimwear:

Before looking at whether or not you can use scuba cloth for swimwear looks at what exactly the scuba fabric is. More often than not, it’s a term that’s used to explain Neoprene. Neoprene is a type of synthetic fabric. In recent years it has come to be as much of a success inside the style community as it’s far in diving circles.

Form-fitting and based, Neoprene has emerged as a famous preference for skirts, attire, and swimming wear. Scuba is durable and resilient like most synthetic. That means it’ll snap back into the vicinity irrespective of how much it can stretch. Scuba becomes notable day by day because of its opaque. For the ones scuba trying to preserve as much of their modesty as they could.

Can Scuba Fabric Influence the Environment?

Yes, it can. On the kind of Neoprene that is made, the commission to which scuba fabric influences the environment depends. The manufacturing of petroleum-primarily based chloroprene rubber, for instance, uses up a limited aid, and it produces waste that often isn’t always disposed of well. The manufacturing of limestone-based total chloroprene rubber, however, is genuinely better for the environment. Limestone isn’t as quick to deliver as petroleum, and you may obtain it more effortlessly than this fossil fuel.

Both forms of polychloroprene, however, are not biodegradable. It might also take lots or tens of millions of years for chloroprene rubber to be reabsorbed into the atmosphere. This material could have blocked waterways, stuffed up forests, and impacted many other ecosystems worldwide within the intervening time.

Frequently Asked Question(FAQ):

Que: What is Scuba Fabric Made of?

Ans: Scuba material is a double knit crafted from polyester and spandex, with a first-rate gauge thread and clean texture. It’s a little springy, very smooth, and has a pleasing drape to it.

Que: What is Scuba Material Used for?

Ans: Scuba material does have an expansion of stop makes use of but is almost exclusively used for style, which is why it turned into created. It is favoured for a few kinds of garments over others even though. Form-becoming attire, swaying skirts, and sports activities garb are very famous when crafted from Scuba cloth.

Que: How Much Does Scuba Fabric Cost?

Ans: Depending on the first-class of the silk, you may discover this cloth ranging in rate from $5 to $65 a yard. But that latter price goes to carry you some premium silk material to put on after you’ve completed your stitching mission. Usually, the charges you will see at maximum outlets may be the decreased stop of the scale, someplace between $5 and 15 according to scuba fabric by the yard.

Que: Is scuba fabric breathable?

Ans: Like neoprene, scuba material isn’t always renowned for being breathable and might get quite warm. However, because of the manner, in which it holds its form, it may be excellent when incorporated into apparel that includes a jacket, top, or as skirt or wintry weather get dressed, and it’s miles frequently utilized in undies.

Que: Is scuba fabric suitable for summer?

Ans: Being a knit material, it’ll also have a selvage aspect and may or might not be reversible. Like neoprene, scuba fabric isn’t famed for being breathable and might get quite a heat, so it might be now not the first-rate fabric desired for a summertime dress.

Que: What is a scuba suit?

Ans: Scuba wetsuits are designed to match near the frame. A loose-fitting wetsuit will allow water to glide inside and out of the gaps between the wetsuit and your pores and skin, which means that your structure will turn out to be losing energy to warm the “new” water, making it unnecessary for thermal insulation.

Conclusion:

One of the motives designers loves scuba is the frame that it offers to clothes. Scuba is made with a total-quality knit gauge and easy thread, which gives it a very smooth finish. The finish also provides the coloration with a matte fine. Scuba material is widely used in a spread of patron and industrial programs. For instance, this type of textile is typically used in the medical field to expand different bureaucracies. I hope you understand perfectly What Is Scuba Double Knit Fabric Details & Use For?

Research Links:

You May Also Read Some Other Related Articles:

- Special Durable Finishes In Textile 2023

- Stripping Process Of Reactive Dyes Of Knitted Fabric

- Can You Dye Viscose And Elastane Fabric?

- What is the best dye for linen? 5 Best Linen Dye Review

- Can You Dye Polyester And Elastane Fabric? A 100% Practical Experiment

You can find us on: