The garment finishing department in the textile industry is the last stage of all processing. So that it needs a standard operating process for better results.

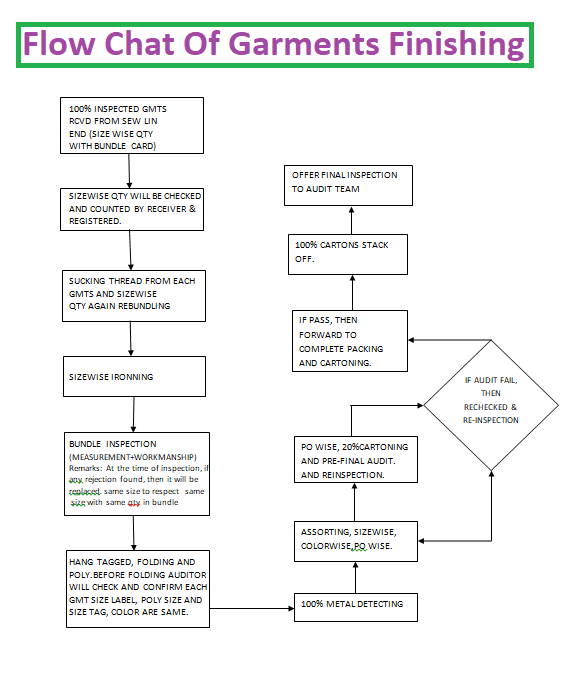

The Flow chart of garments finishing sop is given below:

Start

⇩

Receive the garments from the sewing line according to size with quantity.

⇩

Inspect all the garments according to bundle card size and quantity.

⇩

Count all the quantities and registered.

⇩

Sucking thread from each garment and bundling according to size.

⇩

Size-wise ironing.

⇩

Bundle inspection (At the time of inspection, if any rejection found, then it will be replaced the same size to respect the same size with the same qty in a bundle).

⇩

Hand tag, folding and polibaging ( Autitor will check and confirm all the garments size label, Polibag size, size tag, and color before folding).

⇩

100% Metal detecting.

⇩

Assorting size-wise, color-wise, and po-wise.

⇩

Cartooning 20% PO wise for pre-final audit and rejection.

⇩

If the audit fails, then recheck and re-inspect.

⇩

If pass then go for complete cartooning and packing.

⇩

100% cartoon stack off.

⇩

Offer for final inspection to audit team.

⇩

If ok, then ready for shipment.

⇩

End

You may read some other article:

- Garment Washing Process Flow Chart With Risk Assessment

- What Is Cross And Union Dyeing? Basic Difference Between Them

- What Is The Best Fabric Dye For Jeans? 13 Technical Review 2022

- Fleece Fabric || Dyeing, Finishing, and Testing Of 100% Cotton Fleece Fabric With A Complete Practical Experiment

- Can I Put Rit Dye Directly On Fabric? Some Answers and Myths We’ve Heard

[…] Standard Operating Process (SOP) Flow Chart Of Garments Finishing […]

[…] Standard Operating Process (SOP) Flow Chart Of Garments Finishing […]