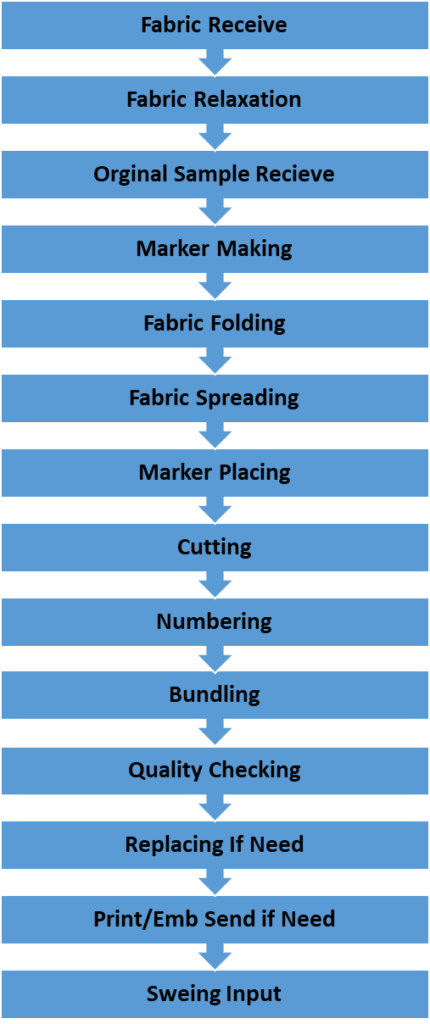

Working Procedure Flow Chart In the Cutting Section is so important for better efficiency and quality cutting. The standard working procedure is given below step by step.

Fabric receive

Fabric Relaxation

Original sample receive

Marker Making

Fabric folding

Fabric spreading

Marker Placing

Cutting

Numbering

Bundling

Quality checking

Replacing if need

Send to print or embroidery if need

Sewing input

Short description of different steps of Working Procedure Flow Chart In Cutting Section

Fabric receives: Normally fabric comes from the dyeing finishing section. It should be more careful to receive the fabric according to the requirement

Fabric relaxation: It is so important for cutting a section of the garments industry. It is needed for better shrinkage and spirality of the fabric. The fabric relaxation time is not the same for all types of fabric. The fabric which has a chance to shrink more then it needs more time for relaxation. Normally Viscose or loose-knit or lycra fabric has a chance to shrink more so it needs more time to relax. The approximate time for viscose or loose-knit fabric or lycra fabric is about 24 hours to 48 hours. For other normal fabrics, 12 hours is enough for relaxation.

Original sample receives: To cut the fabric accurately it needs the original sample and its cutting history if it has been done before. some points must have to do

- Shading Check

- 2. Dia Check

- 3. GSM Check

Marker Making: Needs to make a marker for cutting. It depends on the design and consumption of the garments.

Fabric folding: Needs to fold the fabric in the correct order and folder.

Fabric spreading: It is so important section and it needs some extra process. Some work needs to be done for belief. Some important points should be done are—

- Marker Checking

- Roll Wise Shade Checking

- Dia Checking

Marker Placing: Place the marker according to the planning of cutting. And it should be placed according to the allowance of the fabric.

Cutting: Now it is time to cut the fabric. Some important faults that should be considered before starting cutting are stated below;

- Hole

- Oil spot

- Crease mark Etc

Numbering: After cutting pieces need to number according to the shade and quality of the cut pieces.

Bundling: Bundling Card-Ready before Bundling

Quality checking: All types of quality are checked here before sewing delivery.

Replacing if needed:

Send to print or embroidery if need: Cut pieces need to send to the embroidery or print department if it has print or embroidery in their style requirements.

Sewing input: The final step is to send the pieces to the sewing section to start sewing.

Conclusion:

The flow chart of the working procedure of the cutting section is a 100% applied chart. Some reported factory is already following this procedure.

Research Links:

You can also read some other articles:

- Special Durable Finishes In Textile 2023

- Stripping Process Of Knitted Fabric with Reactive Dyes: Astonishing Results

- What is the best dye for linen? 5 Best Linen Dye Review

- Can You Dye Polyester And Elastane Fabric? A 100% Practical Experiment

You can find us on:

[…] Working Procedure Flow Chart In Cutting Section […]

[…] Working Procedure Flow Chart In Cutting Section […]