The nylon fabric dyeing process is an exclusive dyeing process in the textile industry. There are different nylon dyeing methods available to use. Today I am discussing the nylon fabric dyeing process with acid dyes. These acid dyes are effective for protein fiber. This content will be helpful to us because it is the process which I ueing in my dying factory and getting better results.

As a result wool, silk, nylon, and modified acrylic can dye easily. Acid dyes also have better fastness properties than basic dyes. Acid dyes are highly soluble in water and create a negative charge and interact with the positive charge of fiber. As a result, Van-der-Waals bonds, dipolar bonds, and hydrogen bonds are formed between dye and fiber.

NB: I HAVE DYED A 100% NYLON BLACK COLOR AND GOT A BETTER RESULT. I AM SHARING THESE DOCUMENTS WITH YOU.

100% Nylon Fabric Dyeing Process:

Dyeing of nylon fabric with the acid dying process is below step by step-

Load the fabric

⇓

Normal hot with oxalic acid and detergent

⇓

Raise temperature to 70⁰C

⇓

Run time 10min

⇓

Drain & fill

⇓

Leveling (PH=4.50-5.0)

⇓

Dyes Dosing 20-minute Temperature 40⁰C

⇓

Runtime 10 minute

⇓

Temperature Increase 98⁰C (1⁰C/minute)

⇓

Runtime 30 minute

⇓

Colling 80⁰C (1⁰C/minute)

⇓

Shade check

⇓

If everything ok then

⇓

Bath Drain

⇓

Cold rinse 10 minutes

⇓

Soaping agent Inject (pH5.00)

⇓

Raise the temperature to 80⁰C

⇓

Runtime 15minute

⇓

Cold wash10 minute

⇓

Fixing

⇓

Cold water wash 15 min

⇓

If the water is clear then

⇓

Softener (pH 5.00-5.50)

⇓

Unload

Process Description Of Nylon Dyeing Process:

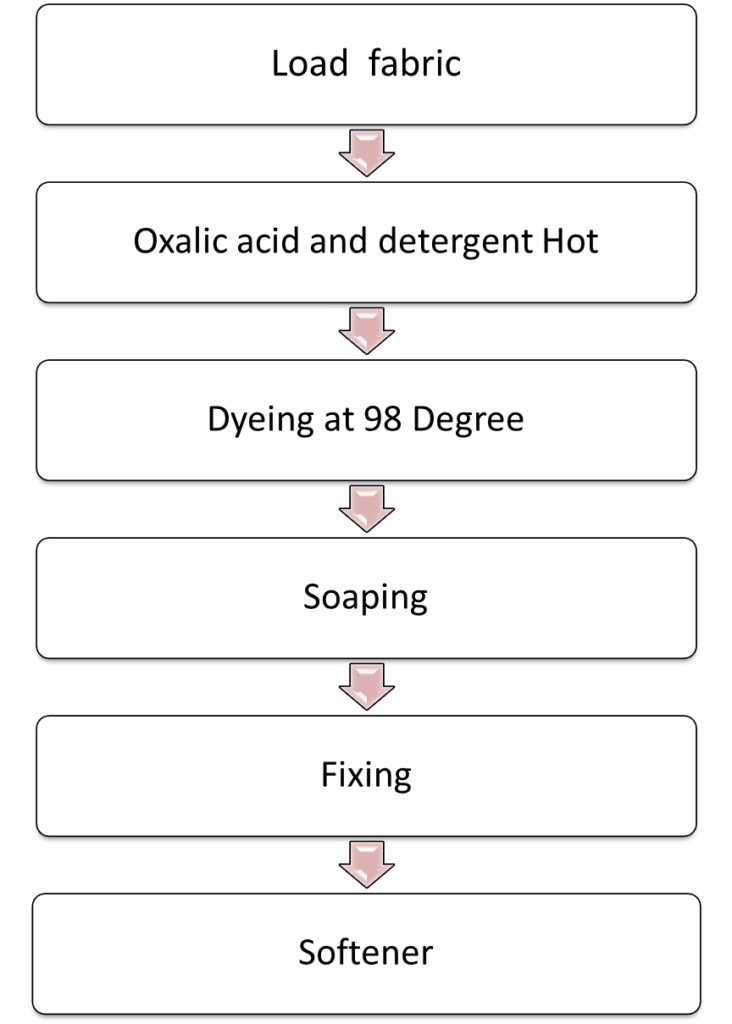

In the nylon fabric dyeing process, Load the fabric at a normal 30⁰Ctemperature. Firstly hot the fabric at 800c with oxalic acid and detergent to remove the dust, dirt, iron, etc. Then Control the pH between 4.5-5. Inject the leveling agent and raise the temperature to 40⁰C. Dossing the dyes for 20min.

After that rise, the temperature was 980c with a grade of 10c per minute. Here grade is essential for better leveling of dyes stuff. Run here for 30min. Cooling at 80 with grade 10⁰C per min. Check the shade with the required standard. Drain the dying bath if the shade is ok.

If it a not okay dye can be added to the dye bath and raise the temperature again. shade check after cooling the at 800c. If ok then drain.

Here rinse with a need of up to 10 minutes to remove the loose dyes from the fabric surface. Speaking needs according to shade %.

Finally, a fixing agent is used for better fix-up of acid dyes and unloading the fabric with ph 5-5.5.

100% Nylon knit fabric dyeing process flow chart:

Conclusion:

This Nylon fabric dyeing process is using many reported factories for production. They get better results from this process. My tips and tricks for using this process for better results-

- PH must have control properly.

- Should not use temperature upper than 100⁰C.

- The Stenter and dryer should be at 100⁰C

In conclusion, using acid dyes to color nylon fabric is a very effective and widely used process in the textile industry. Acid dyes are now the most popular choice for many manufacturers because they last longer and can be used to color protein fibers like wool, silk, nylon, and modified acrylic. The process involves careful control of pH, temperature, and dye dosage to achieve the desired shade and colorfastness.

By following the recommended guidelines and tips, it is possible to achieve consistent and high-quality results in nylon fabric dyeing. As the demand for vibrant and long-lasting colors in textiles continues to grow, the use of acid dyes in the nylon dyeing process is sure to remain a crucial technique in the industry.

Some related questions and answers about the Nylon dyeing process:

- How do you dye nylon fabric?

- Does fabric dye work on nylon?

- Can you dye nylon mesh?

- What is the fabric dyeing process?

Answers:

1. Nylon fabric is dyed with acid dyes.

2. Yes, fabric dye works on nylon.

3. Yes, nylon mesh can be dyed easily.

4. The nylon dyeing process

Research link:

You may read some other articles

- Does Tie Dye Work on Nylon

- What Fabrics Tie Dye Best

- 7 BEST BLACK FABRIC DYES FOR CLOTHES: REVIEWS WITH TIPS AND TRICKS

You can find us on:

[…] Nylon fabric dyeing process- For practical use […]

[…] Nylon fabric dyeing process- For practical use […]

[…] Nylon fabric dyeing process- For practical use […]

[…] Nylon fabric dyeing process- For practical use […]

[…] Nylon fabric dyeing process- For practical use […]

[…] Nylon fabric dyeing process- For practical use […]

[…] Nylon fabric dyeing process- For practical use […]

[…] Nylon fabric dyeing process- For practical use […]

[…] Nylon fabric dyeing process- For practical use […]

[…] Nylon fabric dyeing process- For practical use […]

[…] Nylon fabric dyeing process- For practical use […]

[…] Nylon fabric dyeing process- For practical use […]