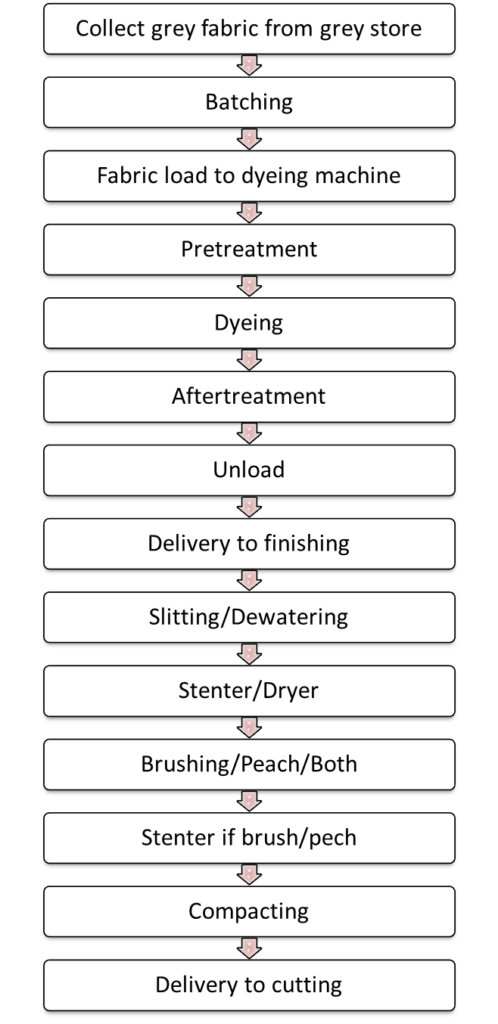

Dyeing is an art that goes hand-in-hand with fabric production. Whether a project involves knitted fabric or something else, the dyeing process is a crucial part of making sure the product meets the highest quality standards. With this in mind, this article will provide a comprehensive overview of the knit dyeing and finishing process flow chart for 2023.

Dyeing is the process of applying the colorant material to the fiber. The knit fabric dyeing and finishing flow chart are discussed below

This is the most recent and technical dyeing flow chart. As a result, this is used all over the world. Lets stated

Short description of process steps:

Grey store: Fabric comes from knitting. Fabric arranges here in a systematic way. Fabric keeping here by considering

- The fabric type like single jersey, terry, and fleece.

- Type of fiber: Cotton, Polyester, Viscose, Lyocell, etc.

- Fabric specification: 100%cotton, CVC, PC, etc.

- yearn lot.

- yearn count.

Batching: The preparation of a batch for a machine according to the Buyer’s order says batching. The function of batching is

- Preparation of batch cards according to buyer order sheet.

- Turning the fabric depends on the type of treatment needed.

- Make a rope for each nozzle.

- Delivery is to the dyeing machine

Pretreatment: Here fabric will be ready for dyeing. The process is given below

- Scoring: Remove impurities like oil, wax, dirty spot, etc.

- Bleaching: Remove the natural color.

- Enzyme: Remove protruding fiber from the surface of the fabric.

Dyeing: A coloring substance applies here to the core of the fiber.

Aftertreatment: Loose dyes removes by soaping here.

Unload: Unload the fabric and delivery it to the finishing department.

Slitting: Fabric is the open hare.

Stenter/Dryer: Fabric dry here. Shrinkage also controls here.

Brush/peach: Brush needs on the fleece fabric. It creates a special effect on the side. On the other hand, peach creates a special effect on the fabric’s surface.

Compacting: Finish the fabric and control the Dia, GSM, Shrinkage, etc.

This is the basic dyeing process flow chart of knit dyeing.

Knit Dyeing Machines

Knit dyeing machines are an integral part of the knit dyeing and finishing process. The process starts with the preparation of the fabric and ends with finished dyed and finished products. The flowchart includes processes such as fabric preparation, dyeing, rinsing, drying, finishing, and quality control checks. The use of knit dyeing machines in this process ensures consistent and high-quality results.

Conclusion:

In conclusion, the knit dyeing and finishing process flow chart 2023 provides a clear, step-by-step guide to completing the whole process. So It is important to note that each type of material and design has unique dyeing and finishing requirements so it is necessary to be aware of these before commencing the process. The chart also helps to identify any potential problems which can arise during dyeing, such as color running or producing an uneven finish.

Research link:

You may read some other articles

- Textile Dyeing Processes for Practical Use

- What Is Color Fastness In Textile? | 16 Types | Methods | Importance

FOR MORE INFO VISIT KNIT DYEING DETAILS

[…] for the cotton dyeing process. This dyeing mechanism occurs only in the dyeing portion of the dyeing process flow chart. which are given […]

[…] dyeing flow chart- with successful implementation practically 2021 […]

[…] dyeing flow chart- with successful implementation practically 2021 […]

[…] dyeing flow chart- with successful implementation practically 2021 […]

[…] dyeing flow chart- with successful implementation practically 2021 […]

[…] dyeing flow chart- with successful implementation practically 2021 […]