The natural dyeing process of cotton is the application of natural dyes to the fiber molecules of cotton fabric. It is the most recent technology in the sense of sustainability. It is the most popular dyeing procedure at present. Because less amount of hazardous chemicals is used here. As a result, users switch to using naturally dyed products.

Dyeing fabric has been a part of human culture for centuries, and natural dyeing processes are still popular today. Cotton is one of the most commonly used fabrics in the world. Those who want to try out different ways of dying cotton might find it helpful to know the pros and cons of natural dyeing processes.

Now a practically applied procedure is discussed below, along with its advantages and disadvantages.

Process flow chart of natural dyeing of cotton:

Remove impurities

⇩

Then the fabric is immersed in the dye bath

⇩

Agitated carefully

⇩

Then rinse the water carefully

⇩

Dried and finish

The natural dyeing of cotton process flow chart includes several steps. The cotton fabric is scoured first to remove any impurities or chemicals that may be present on the fabric’s surface. The fabric is then mordanted to improve dye uptake and colorfastness. The mordanted fabric is then immersed in a natural dye bath made from plant-based dyes like indigo, turmeric, and madder. To ensure even dye distribution, the fabric is carefully agitated in the dye bath. The fabric is rinsed and washed after dyeing to remove any excess dye or mordant. Finally, to achieve the desired properties, the fabric is dried and finished.

Natural dyeing is an environmentally friendly process because it uses renewable and biodegradable plant-based sources. It also produces distinct and vibrant colors that synthetic dyes cannot match. However, natural dyeing has some drawbacks, including limited color options, uneven dye uptake, and poor colorfastness. Mordanting can also be time-consuming and requires careful handling to avoid health risks. Overall, natural cotton dyeing is a sustainable and artistic method of producing textiles, albeit with some limitations.

History of natural dyeing:

The history of natural dyeing dates back to ancient times, with evidence of dyeing fabrics with natural materials found in various civilizations, including Egypt, India, China, and South America.

In ancient Egypt, for example, the use of natural dyes was documented in hieroglyphs and artifacts dating back to around 2500 BCE. The Egyptians used various natural materials, including indigo, madder, and saffron, to dye fabrics.

In India, natural dyeing has been practiced for more than 5,000 years, with many of the techniques and materials still in use today. Indian artisans use a range of natural materials, including turmeric, indigo, and madder, to create vibrant colors.

In China, natural dyeing was also widely practiced, with materials such as indigo, safflower, and silk being dyed with natural materials. The Chinese also developed sophisticated techniques for creating intricate patterns and designs using natural dyes.

In Europe, the use of natural dyes became widespread during the Middle Ages, with materials such as woad, madder, and weld being used to create a range of colors. However, the popularity of natural dyes declined in Europe during the Industrial Revolution, as synthetic dyes became more widely available and less expensive.

Today, there is renewed interest in natural dyeing, with artisans and designers around the world using natural materials to create unique and sustainable textiles.

Natural dyeing process of cotton in detail at the factory level:

Load the fabric

⇓

Detergent, sequestering agent, and creasing agent injects at 40⁰C

⇓

Raise temperature to 50⁰C

⇓

Caustic soda dossing=7minute

⇓

Raise temperature at 70⁰C

⇓

Inject H2O2

⇓

Raise temperature at 98⁰C

⇓

Runtime = 60min

⇓

Cooling at 78⁰C

⇓

Sample check (Absorbency and brightness)

⇓

If the sample is ok then drain

⇓

Wash clear

⇓

Raise temperature at 55⁰C

⇓

Control ph=4.5

⇓

The enzyme (Bio polishing) inject

⇓

Runtime =60min

⇓

Check sample (Haireyness)

⇓

If ok then drain

⇓

Wash clear

⇓

Leveling agent injects at 30⁰C temperature.

⇓

Runtime=5min

⇓

Salt dossing =15min

⇓

Runtime =10min

⇓

Color dossing=30min

⇓

Runtime=30min

⇓

Sample check for availability of dyes

⇓

Raise temperature at 80⁰C (Grade=1⁰C/min)

⇓

Runtime=45min

⇓

Cooling 78⁰C

⇓

Check sample

⇓

If ok then drain

⇓

Wash clear

⇓

Raise temperature at 70⁰C

⇓

Runtime=10min

⇓

Drain and wash clear

⇓

Softener and unload

⇓

Delivery to finishing

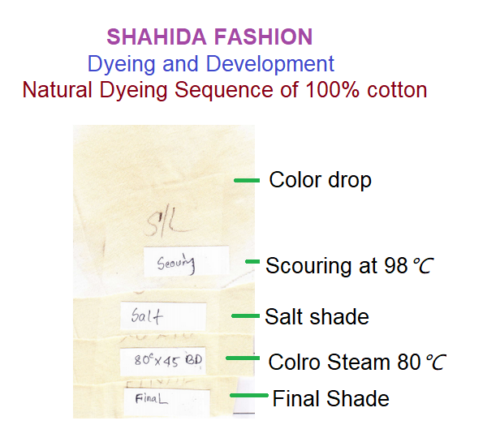

Complete documentation of the practical natural dyeing process of cotton with a diagram

Fabric: 100% cotton fabric.

Color: Yellow

Preparation of Dyeing recipe:

| REQUISITION FO DYESTUFF & CHEMICALS |

| Date : | 00-00-00 |

| Batch No : | 1000 |

| Shade/Color : | Yellow |

| Quantity : | 1000Kg |

| L.:R. : | 1:8 |

| Total Water : | 8000 Ltr |

| Buying House :Practical TextileBuyer 😛 TOrder No :100Machine No : Type of fabric :100% cottonSro No : Dyeing Recipe: |

| SL# | Name of the chemicals | G/Liter | % | Req’d Qty. In Kg | Issues Qty. | Remarks |

| Pretreatment : | ||||||

| 1 | Detergent | 1 | 8.000 | |||

| 2 | Anticreasign agent | 2 | 16.000 | |||

| 3 | Caustic | 2.0 | 16.000 | |||

| 4 | H2O2 | 2.5 | 20.000 | |||

| 5 | Acetic Acid | 8.000 | Depends | |||

| 6 | Peroxide killer | 0.15 | 1.200 | |||

| 7 | Enzyme | 0.25 | 2.000 | |||

| Dyeing : | ||||||

| 8 | Leveling agent | 1.00 | 8.000 | |||

| 9 | Anti creasing agent | 1.00 | 8.000 | |||

| 10 | Yellow xx | 3.0 | 30.000 | |||

| 11 | ||||||

| 12 | Glober Salt | 30.0 | 240.000 | |||

| After Treatment : | ||||||

| 13 | Soaping agent | 1.0 | 8.000 | |||

| 14 | Anti creasing agent | 1.0 | 8.000 | |||

| 15 | ||||||

| 16 | Fixing agent | 1.0 | 8.000 | |||

| 17 | Softener | 1.0 | 8.000 |

PRACTICAL TEXTILE PRACTICAL TEXTILE

Issued Prepared by

NB: all the dyes and chemical dossing depends on the supplyer recomendation.

Dyeing sequence:

We cut the sample for every stage of the natural dyeing process. As a result, you can understand easily. This is an example of a re-updated factory.

After unloading the fabric we send it to the finishing department.

After that slitting> stenter> compacting occurs. Finally, we got the finished fabric.

The finished fabric picture is here

Natural dyeing is an eco-friendly dyeing process. The output product of natural dyeing is a health response. So that everyone should use this product. In natural dyeing, there is some advantage and disadvantage.

Advantages of the natural dyeing process of cotton or dyes stuff:

- Eco-friendly dyes.

- These dyes are made from natural sources. As a result, they are sustainable because the dyed cellulosic fabric contains no hazardous man-made chemicals like Azo pigments or Azo dyestuffs.

- The natural colors are exhausted completely. As a result, the drain water is spotless. Also, the first rinsing bath will be completely clean. This is a sustainable dyestuff because there are no residues from the binder. Here are pigments in the drained water and rinsing bath.

- Natural dyes used in textiles contain no Azo dyes, which means the recycling of used clothes is sustainable, which means the pigments are suitable for the “cradle-to-cradle” philosophy.

Disadvantages of the natural dyeing process of cotton:

- The color range is limited. So, various color is not possible.

- The fastness properties of natural dyes are not up to the mark specially the light and color changes after washing. Generally, the light fastness for light colors 1-2. For dark color 3. change of color after wash 3.

- Shade variation is more than the normal dyeing process.

- Discharge print is not possible.

- Even dyeing is not possible usually.

Conclusion:

The world is going toward sustainability So natural dyeing is the better option for sustainability. You must have used it to keep yourself safe.

Research link:

You may read some other articles

FOR MORE INFO VISIT KNIT DYEING DETAILS

[…] natural dyeing process of cotton- For practical use & experiment […]

[…] natural dyeing process of cotton- For practical use & experiment […]

[…] natural dyeing process of cotton- For practical use & experiment […]

[…] natural dyeing process of cotton- For practical use & experiment […]

[…] natural dyeing process of cotton- For practical use & experiment […]

[…] natural dyeing process of cotton- For practical use & experiment […]

[…] natural dyeing process of cotton- For practical use & experiment […]

[…] natural dyeing process of cotton- For practical use & experiment […]

[…] natural dyeing process of cotton- For practical use & experiment […]